In modern electronic devices, integrated circuits (ICs) are core components that carry complex computing tasks and high-load work. However, as the heat generated by these IC devices increases, heat dissipation has become an important part of the design. IC thermal pads are an ideal choice to solve thermal management problems.

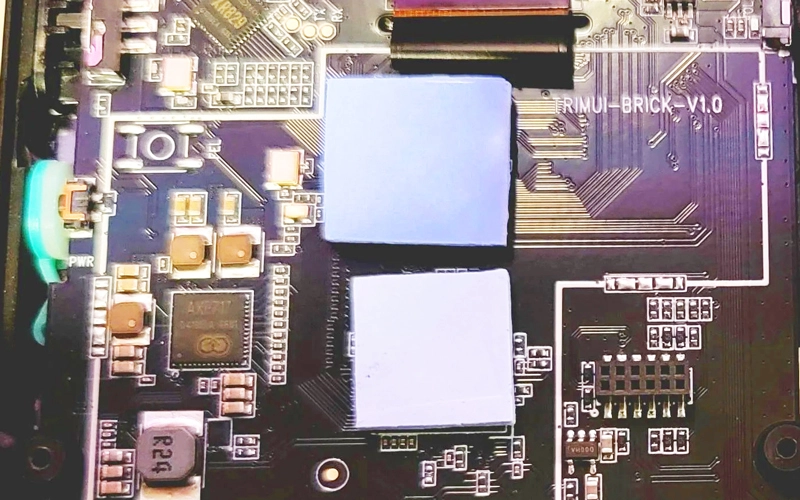

IC thermal pads are a type of thermally conductive material used to dissipate heat in electronic devices. They are usually made of silicone, graphite or other thermally conductive polymers. Their main function is to help electronic components dissipate heat. It fills the gap between the integrated circuit and the heat sink, providing a more efficient heat conduction path and reducing heat accumulation, thereby protecting the IC from overheating damage.

IC thermal pads transfer heat from integrated circuits to heat dissipation devices such as heat sinks or radiators through their high thermal conductivity. This heat transfer process helps reduce the temperature of electronic components, ensuring that they operate in optimal working conditions and avoiding performance degradation or device failure due to overheating.

● Thermal Conductivity

The thermal conductivity of the IC thermal pad directly affects the heat dissipation effect. Choosing materials with higher thermal conductivity can conduct heat more effectively and improve heat dissipation performance. Common thermal conductive materials include silicone, graphite, ceramics, and metals. Generally, the higher the thermal conductivity, the better the thermal management effect.

● Thickness

The thickness of the thermal pad determines the contact area between it and the IC and the heat sink. The right thickness can ensure that the heat is fully conducted. A thermal pad that is too thick may cause poor contact and reduce heat dissipation efficiency; a pad that is too thin may not effectively fill the gap and cause heat accumulation.

● Flexibility

IC thermal pads usually require a certain degree of flexibility to accommodate IC packages of different shapes and sizes. Soft thermal pads can better fill the contact surface and ensure that heat can be evenly distributed to the heat sink.

● Heat resistance

In high temperature environments, IC thermal pads need to maintain good thermal conductivity. Therefore, it is particularly important to choose a thermal pad that is resistant to high temperatures to avoid aging or failure of the thermal pad during long-term use.

● Electrical insulation

Many IC thermal pads also need to have electrical insulation properties to prevent current leakage or short circuits. This is especially important, especially in high-frequency or high-voltage electronic devices.

● Consumer electronics

In consumer electronics such as smartphones, tablets, and laptops, IC thermal pads are mainly used to dissipate heat from high-heat electronic components such as processors (CPUs) and graphics processing units (GPUs). Effective heat dissipation ensures that the device can maintain stable performance even when running at high loads for a long time.

● Automotive electronics

With the continuous development of automotive intelligence, electronic systems are becoming more and more complex, including autonomous driving systems, in-vehicle entertainment systems, engine control units (ECUs), etc. IC devices in these systems usually require efficient heat dissipation management to ensure that electronic components can still operate reliably in the high temperature environment inside the car. IC thermal pads play a vital role in these applications.

● Industrial equipment

In the fields of industrial automation, robot control, sensors, and communication equipment, IC thermal pads are also used to ensure the thermal stability of electronic components. These devices usually need to run 24 hours a day, so thermal management has become the key to improving equipment reliability and extending service life.

● LED lighting

In high-power LED applications, thermal management is crucial. IC thermal pads can help LED modules dissipate heat quickly, improve their working efficiency and service life. Especially in high-brightness LED lamps and smart lighting equipment, the role of thermal pads is particularly important.

IC thermal pad is an indispensable heat dissipation material in electronic devices. Its performance directly affects the temperature control effect and working stability of electronic components. Understanding the selection factors, application fields and correct installation methods of IC thermal pad can help engineers and designers better optimize the heat dissipation system of electronic products and improve the long-term reliability and performance stability of the equipment.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com