Will Heat Make the Thermal Heating Pad Softer?

- Posted on:2023-04-23 15:26:00

- Source:AOK Thermal Pad Manufacturer FAQs

Heat can soften the thermal pad. Thermal pads are designed to conduct heat, and as they are exposed to heat, they become more flexible and conform better to the surfaces they touch. However, it is important to note that excessive heat can also cause the thermal pad to fail and lose effectiveness over time.

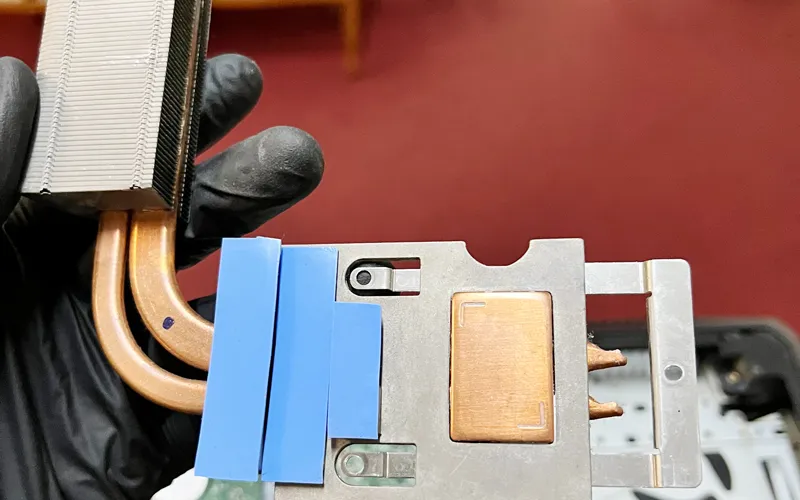

Thermal pads are heat-conducting media that fill the air gap between heating components of electronic products and heat sinks or metal casings. The flexible and elastic characteristics of thermal pads allow them to be used to cover very uneven surfaces. Heat is conducted from the entire PCB to the metal housing or diffuser, which improves the efficiency and lifespan of heat-generating electronic components.

Features of thermal pads

• The material is soft, has good compression performance, good thermal conductivity and insulation performance, and the adjustable range of thickness is relatively large. It is suitable for filling cavities. Both sides have natural stickiness, strong operability and maintainability

• The main purpose of selecting thermal pads is to reduce the contact thermal resistance between the surface of the heat source and the contact surface of the heat dissipation device. The thermal pads can well fill the gap between the contact surfaces

• Since air is a poor conductor of heat, it will seriously hinder the transfer of heat between the contact surfaces, and installing a thermal pad between the heat source and the radiator can squeeze the air out of the contact surface

• With the addition of thermal pads, the contact surface between the heat source and the radiator can be fully contacted better, and the face-to-face contact can be truly achieved, and the temperature response can achieve the smallest possible temperature difference

• The thermal conductivity of the thermal pad is adjustable, and the thermal conductivity is better

• The structural gap between the heat conduction pad and the process gap is bridged, and the requirements for the gap between the radiator and the heat dissipation structure are reduced

• The thermal pad has insulating properties (this feature needs to be added with suitable materials during production)

• The thermal pad has the effect of shock absorption and sound absorption

• The thermal pad has the convenience of installation, testing and reusability

The hardness of the thermally conductive silicone pad and the thickness of the thermally conductive silicone pad are inseparable from the heat conduction effect. We should start with the thermal conduction path and principle of the thermal silicone pad. First of all, we should be clear that when the thermal conductive silicone pad is pasted on the heating part, the lower the hardness of the thermal conductive silicone pad and the softer it is, the more fully the contact between the thermal conductive silicone pad and the heating part will be, and the larger the contact area will be. In this way, due to the increase of the effective contact area, the heating speed of the heating component transmitted through the heat-conducting silicone pad will be faster, and the heat conduction effect will be better.

How to use thermal pads

1. Keep the surface of the thermal pad clean and prevent the thermal pad from sticking to dirt. The self-adhesive and sealing thermal conductivity of the dirty thermal pad will deteriorate

2. When picking up the heat conduction pad, the heat conduction pad with a large area should be grasped from the center, and the sheet with a small area is not required to be grasped, because the uneven force of the large heat conduction pad will cause deformation and affect the follow-up operation, or even damage the thermal pad

3. Hold the sheet with your left hand, and tear off one side of the release protective film with your right hand. The protective film on both sides cannot be torn off at the same time, reducing the number and area of direct contact with the thermal pad

4. Tear off one side of the protective film, facing the radiator, first align the thermal pad with the radiator, when slowly lowering the thermal pad, be careful to avoid the generation of air bubbles

5. If air bubbles are generated during the operation, you can pull up one end of the thermal pad and repeat the above steps, or use a tool to gently wipe off the air bubbles, but the force should not be too large

6. Tear off the protective film on the other side and put it into the radiator. The strength to tear off the last protective film should be small to avoid straining or pulling up the thermal pad

7. After fastening or using a strong adhesive thermal pad, apply a certain pressure on the radiator and store it for a period of time to ensure that the thermal pad is fixed

Correct selection of thermal pads is the key to ensure high heat dissipation of equipment. For the same thermal pad product, there are generally pads with multiple specifications of thermal conductivity to choose from. When selecting a thermal pad, it is necessary to choose a thermal pad reasonably based on the physical properties, pressure, temperature, size of the equipment, operating conditions, and the length of the continuous operation cycle of the thermal pad, maximize the strengths and avoid weaknesses, and give full play to the characteristics and advantages of the thermal pad.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.