Security Products Thermal Solution

-

Solution Overview

The role of heat-conducting materials in monitoring equipment is to quickly transfer the heat generated inside the equipment to the outside to achieve the purpose of heat dissipation. A certain amount of heat will be generated inside the monitoring equipment. If the heat cannot be dissipated in time, it will affect the performance and life of the equipment.

Thermally conductive material is a material with high thermal conductivity, such as heat dissipation glue or heat dissipation pad. These materials can effectively transfer heat to the device casing, and then release the heat to the outside through ways such as heat sinks or cooling holes on the casing.

In the design and manufacture of monitoring equipment, the selection and application of thermally conductive materials are very important. The better the thermal conductivity of the thermally conductive material, the faster the heat inside the device can be transferred to the outside, thereby improving the heat dissipation effect of the device. In addition, the reliability, stability and safety of thermally conductive materials are also factors that need to be considered.

Therefore, thermally conductive materials play an important role in monitoring equipment, which can help the equipment to dissipate heat better and ensure the performance and life of the equipment. At the same time, monitoring equipment designers should fully consider the heat dissipation problem when designing, and use casings and heat sinks with reasonable heat dissipation design to increase the heat dissipation area to ensure that the equipment can dissipate heat quickly, thereby improving the stability and reliability of the equipment.

The current mainstream camera 720P is gradually moving towards high-end, with high-definition pixels, 1080P, 4K image quality, etc., the demand for thermal interface materials will also increase to 6W-15W, and the oil separation of thermal interface materials will be higher.

-

Solution

Security industry classification

Product model details

Product model detail diagram

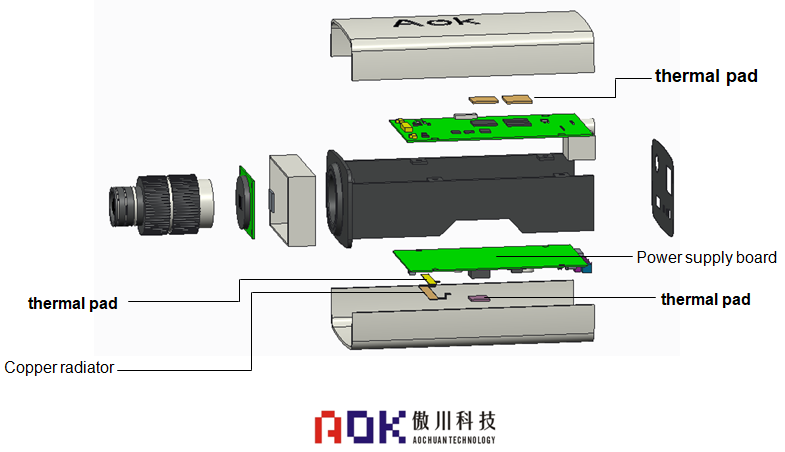

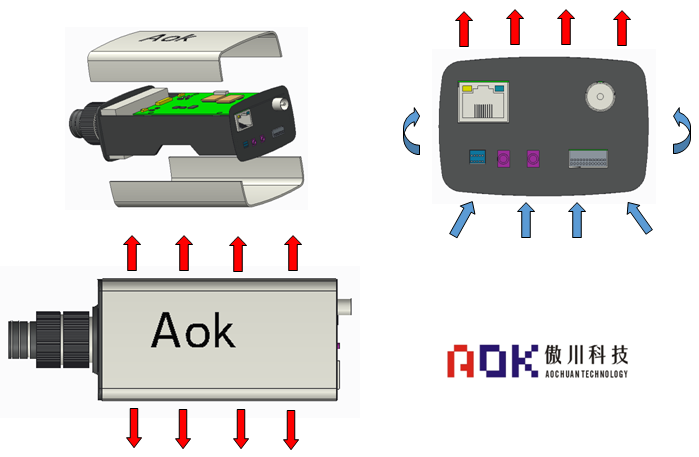

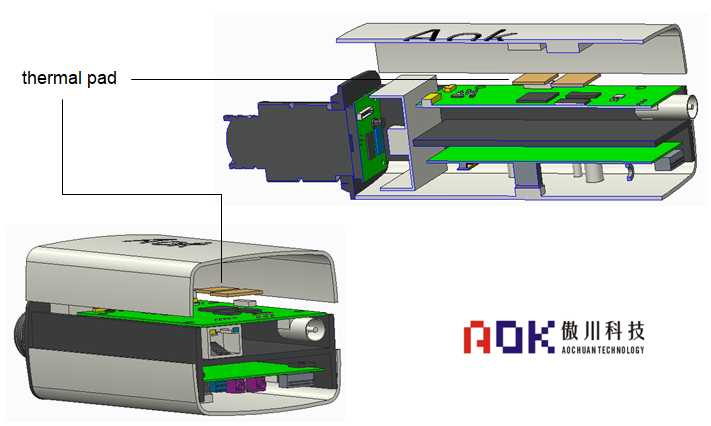

Schematic diagram of the structure of the box camera

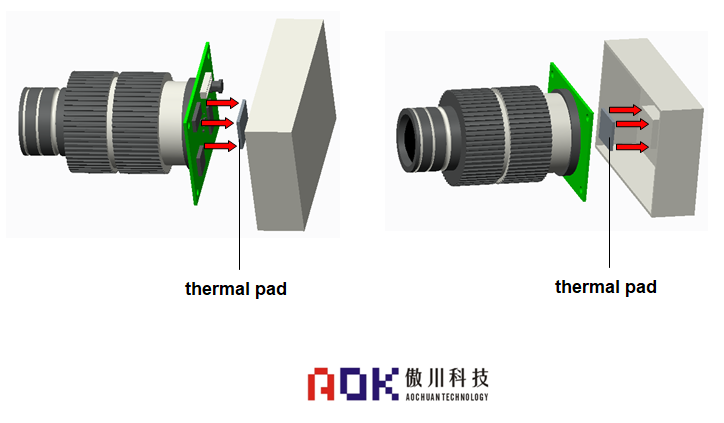

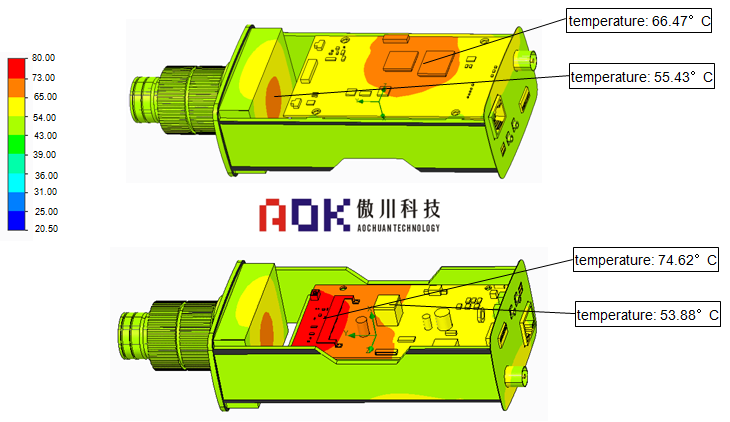

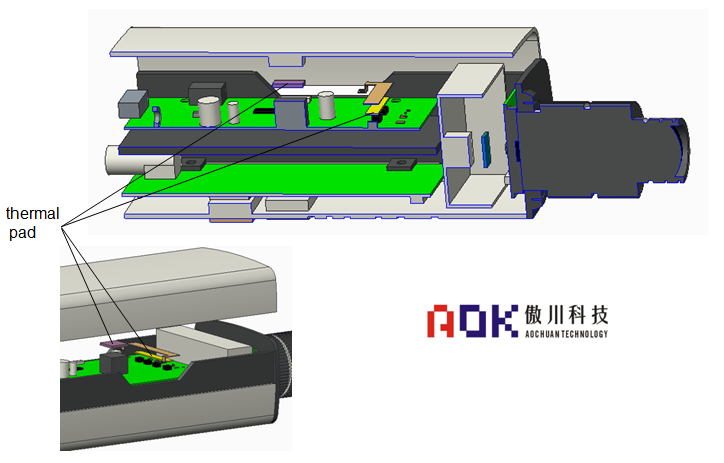

Heat dissipation structure diagram-image processing module

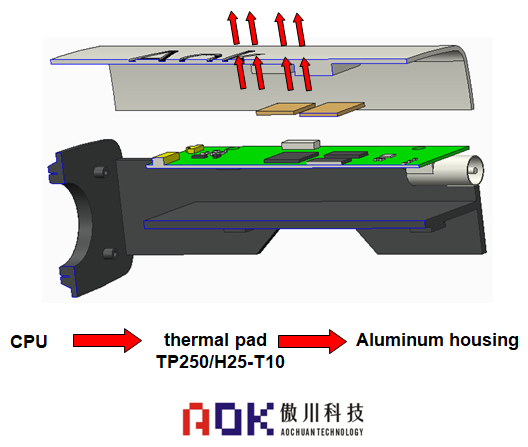

Heat dissipation structure-A board heat dissipation icon

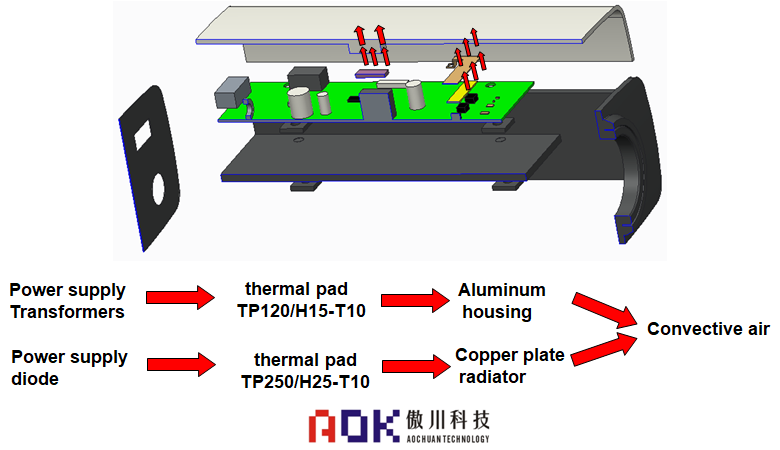

Heat dissipation structure-power board heat dissipation icon

Schematic diagram of shell heat conduction

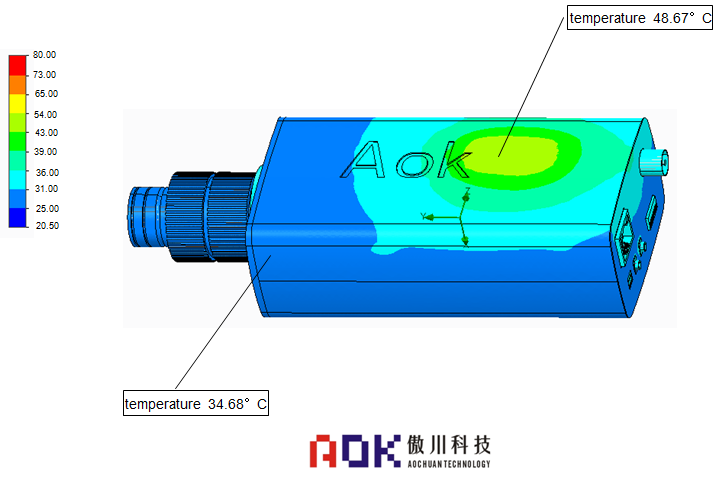

Schematic diagram of temperature rise

Product application scenarios

Product application scenarios

Main heating chip power and thermal interface material selection-image processing module

Heat source power Materials used Usage special requirements 720P-1.0-1.5W/

1080P-2.5-3.5W/ 4K-6W+thermal pad

Thermal Conductivity: 1.5-6W/m.k

Thickness: 0.5-1.0mm

Breakdown Voltage: 6kvThe image processing module on the PCB board generates a large amount of heat and requires independent heat dissipation. The thermally conductive silicone sheet is attached to the pins on the back of the module to conduct the heat of the image processing module to the aluminum back cover for heat dissipation. Hardness: less than 20 degrees Shore 00, super soft material with low oil separation or no silicon material (oil separation will cause pollution to the photosensitive module and affect the image quality.) Low volatility test standard: put the thermal conductive material in a closed beaker and cover it Frosted glass cover, burned in a 80°C oven for 48 hours, without volatile oil stains. Selection of main heating chip power and thermal interface material-A board

Heat source power Materials used Usage 1-4W thermal pad

Thermal Conductivity: 1.5-2.0W/m.k

Thickness: 0.5-1.0mm

Breakdown Voltage: 6kvFill the gap between the heating electronic components (CPU & memory/video memory) on the A board and the aluminum die-casting shell, and conduct the heat to the shell for heat dissipation. Selection of main heating chip power and thermal interface material-Power Board

Heat source power Materials used Usage 1-2.5W thermal pad

Thermal Conductivity: 1.0-1.5W/m.k

Thickness: 0.5-1.0mm

Breakdown Voltage: 6kv1、Filling heat conduction between the transformer on the power board and the aluminum die casting shell.;

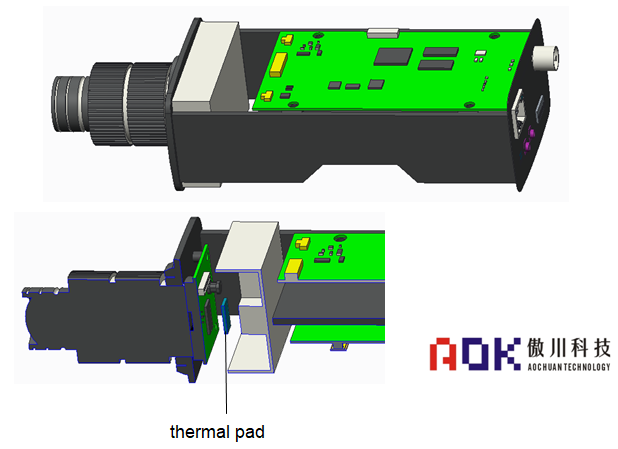

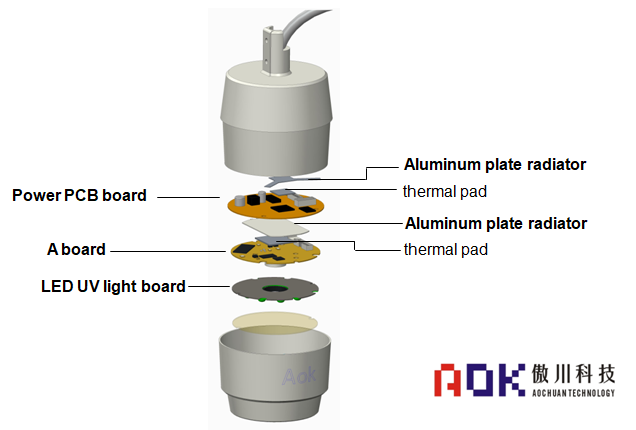

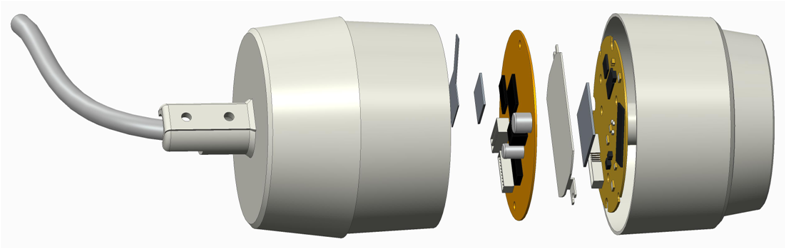

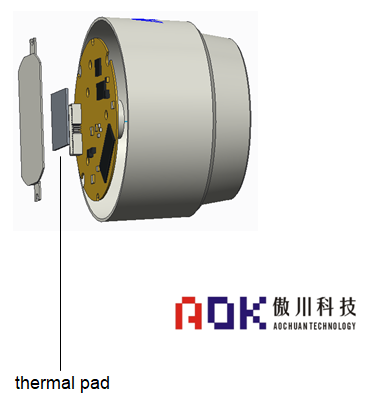

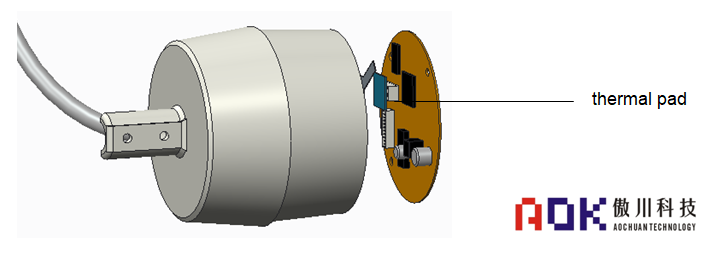

2. The filling between the diode on the power board and the copper radiator conducts heat.Schematic diagram of the structure of the tube camera

Drum machine heat dissipation structure diagram

Main heating chip power and thermal interface material selection-image processing module

Heat source power Materials used Usage special requirements 720P-1.0-1.5W/ 1080P-2.5-3.5W/ 4K-6W+ thermal pad

Thermal Conductivity: 1.5-6W/m.k

Thickness: 0.5-1.0mm

Breakdown Voltage: 6kvThe image processing module on the PCB board generates a large amount of heat and requires independent heat dissipation. The thermally conductive silicone sheet is attached to the pins on the back of the module to conduct the heat of the image processing module to the aluminum back cover for heat dissipation. Hardness: less than 20 degrees Shore 00, super soft material with low oil separation or no silicon material (oil separation will cause pollution to the photosensitive module and affect the image quality. ) Selection of main heating chip power and thermal interface material-A board

Heat source power Materials used Usage 1-4W thermal pad

Thermal Conductivity: 1.5-2.0W/m.k

Thickness: 0.5-1.0mm

Breakdown Voltage: 6kvFill the gap between the heating electronic components (CPU & memory/video memory) on the A board and the aluminum die-casting shell, and conduct the heat to the shell for heat dissipation.