Power Supply Adapter Thermal Solution

-

Solution Overview

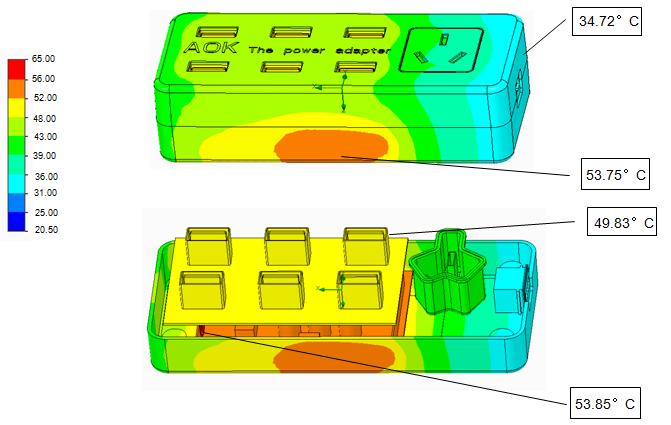

We often come into contact with the power adapter in our daily life, and it will become hot and hot after long-term use. If the temperature of the power supply is too high during use, it will seriously affect the product performance and even be a safety hazard. It is very necessary to choose suitable thermal conductive materials to help the power supply dissipate heat and improve the stability of the product.

-

Solution

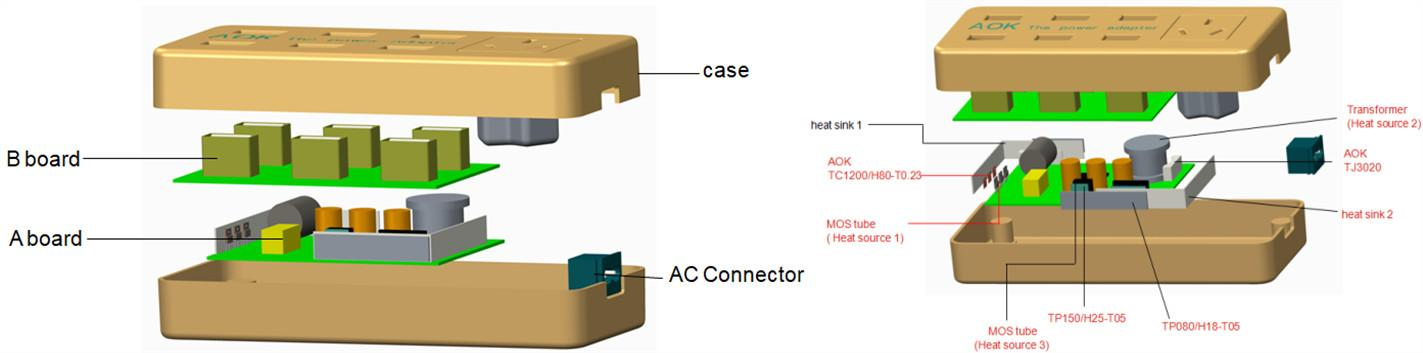

Power Supply Adapter Thermal Solution

The heat dissipation of the power adapter is very important, because high temperature may affect the stability and life of the power adapter. Here are some effective cooling methods:

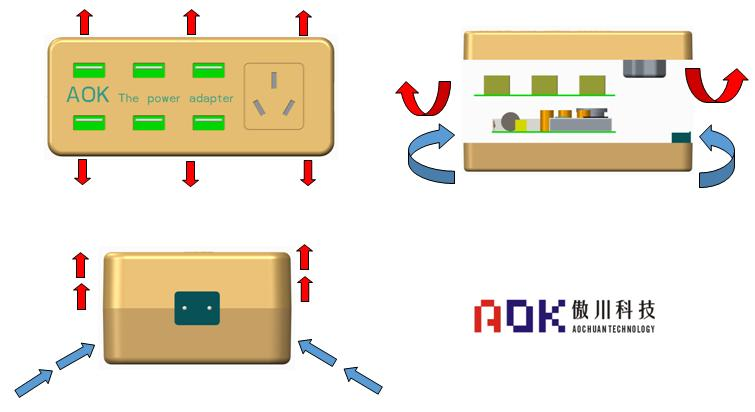

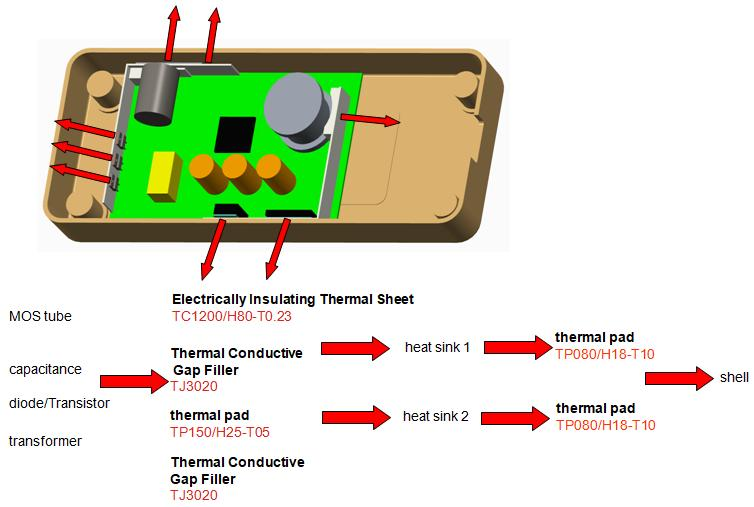

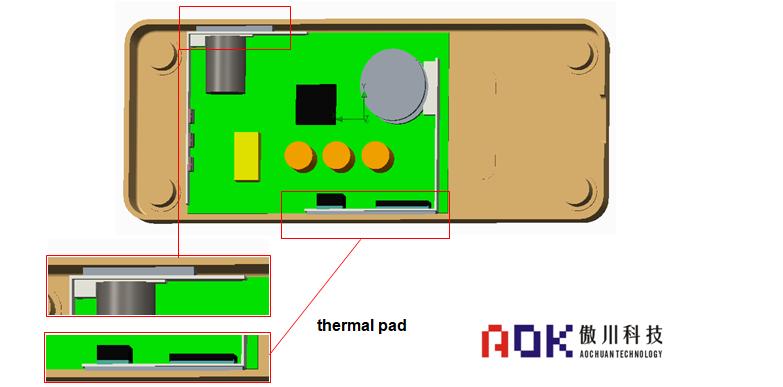

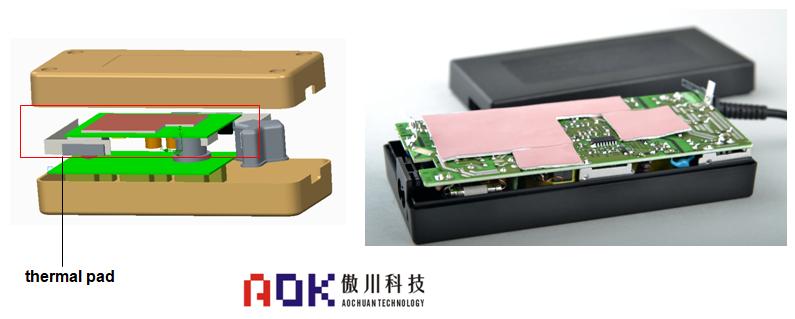

Optimize the design of the power adapter, adopt a reasonable heat dissipation design shell and heat sink, and increase the heat dissipation area. Select high-efficiency, low-power electronic components and circuit design to reduce power consumption and heat generation. Appropriate ventilation design includes adding cooling holes on the adapter shell, or adopting active cooling methods such as fans to increase airflow and discharge heat. Use thermally conductive materials, such as high thermal conductivity silicone or metal guides, to transfer heat from the electronic components to the housing. Avoid placing the power adapter in a high temperature or closed environment, which will cause excessive heat and affect the cooling effect.

It should be noted that the heat dissipation design should match the power and load of the adapter, so when designing and selecting a power adapter, the heat dissipation problem should be carefully considered to ensure the stability and life of the adapter.

Industrial power adapter

An important trend in the power adapter market is the need for adapters with higher output power, lower no-load energy consumption, and smaller size. This requires transformers and MOS tubes to have higher stability and functions of voltage and current conversion. The heat dissipation requirements will be more demanding, so the structure of the heat sink in the future will be smaller and smaller, and the thermal interface materials will also tend to have better thermal conductivity, better insulation, breakdown voltage, and tear strength.

Consumer power adapter

The diversification of the output of consumer power adapters is an important trend in future development. The diversification and penetration of electronic equipment makes conventional home adapters unable to meet the demand at all; emerging technologies such as fast charging, wireless charging, high voltage, and low voltage will become more important. In order to be frequently implanted in consumer power adapters, such products have higher power consumption and stricter requirements for heat dissipation, and the thermal conductivity of thermal interface materials will be higher and higher.

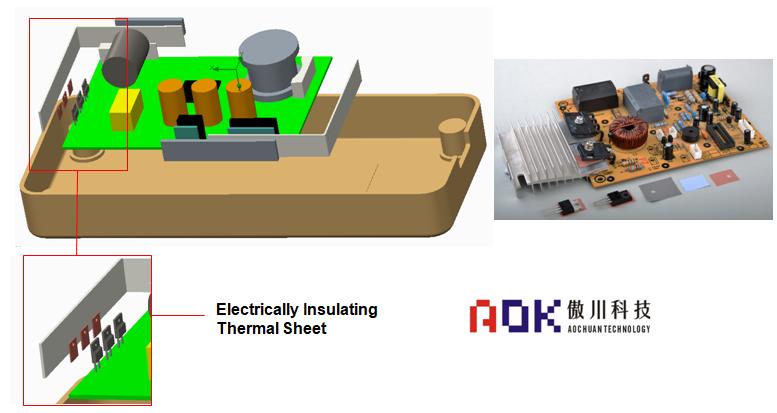

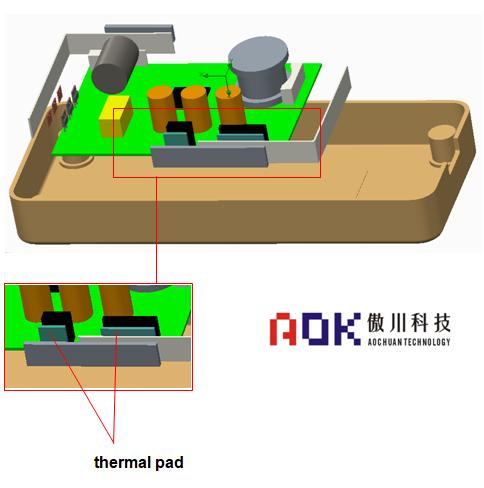

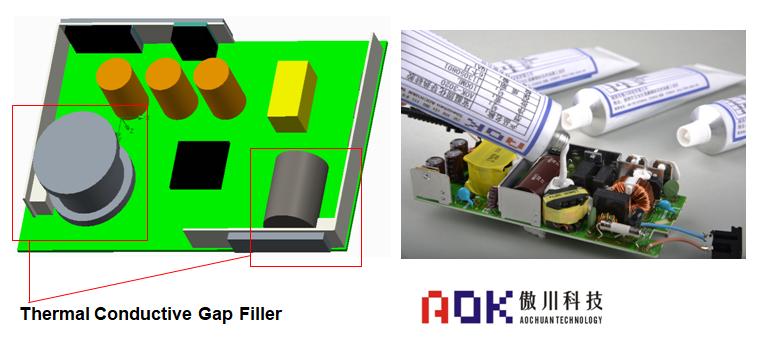

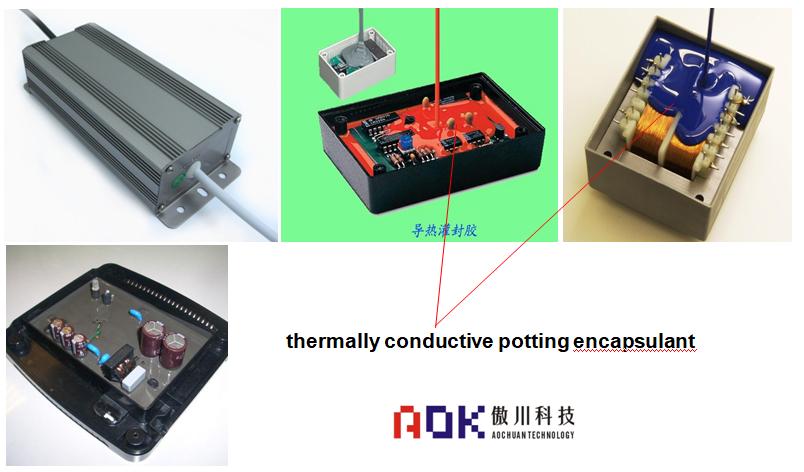

The function of the thermally conductive material in the power adapter is to quickly conduct the heat generated inside the power adapter to the outside to achieve the purpose of heat dissipation. A certain amount of heat will be generated inside the power adapter, if the heat cannot be dissipated in time, it will affect the performance and life of the adapter.

Thermally conductive material is a material with high thermal conductivity, such as silicone or metal guide plate. These materials can effectively transfer heat to the adapter housing, and then release the heat to the outside through the cooling fins or cooling holes on the housing.

In the design and manufacture of power adapters, the selection and application of thermally conductive materials are very important. The better the thermal conductivity of the thermally conductive material, the faster the heat inside the adapter can be transferred to the outside, thereby improving the heat dissipation effect of the adapter. In addition, the reliability, stability and safety of thermally conductive materials are also factors that need to be considered.

Therefore, thermally conductive materials play an important role in the power adapter, which can help the adapter to dissipate heat better and ensure the performance and life of the adapter.