Why Compress Soft Silicone Thermal Pad to 2/3 Thickness?

- Posted on:2025-02-25 09:21:00

- Source:AOK Thermal Pad Manufacturer FAQs

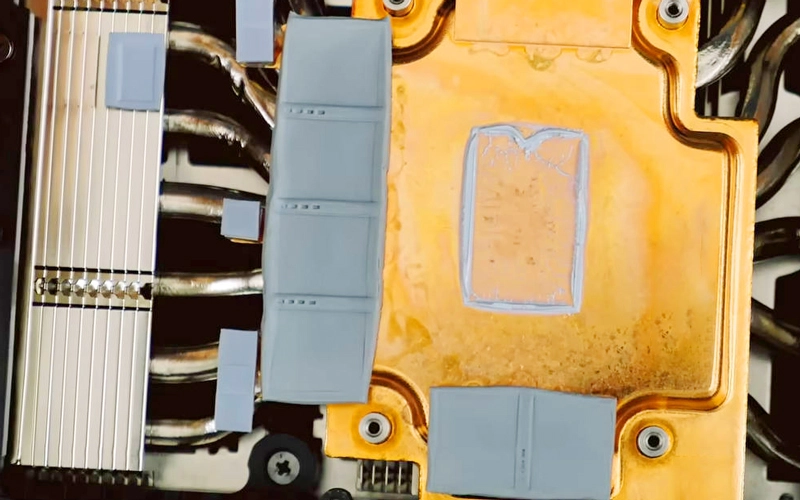

Soft silicone thermal pads need to be compressed to at least two-thirds of their original thickness to ensure they effectively transfer heat between surfaces, such as a CPU and a heatsink.

Improved Surface Contact

When compressed, a soft silicone thermal pad molds itself to the uneven surfaces it’s placed between. This eliminates air pockets—since air is a poor conductor of heat—and maximizes the contact area, allowing heat to flow more efficiently from the heat source to the heat sink.

Optimal Density for Heat Transfer

At two-thirds of its original thickness, the pad achieves the density it’s designed for, striking a balance between flexibility and thermal conductivity. If it’s not compressed enough, the pad remains too loose, reducing its ability to conduct heat effectively. Over-compressing beyond this point, however, might limit its capacity to fill tiny surface imperfections.

Reduced Thermal Resistance

Compressing the pad lowers its thermal resistance, which is a measure of how much it impedes heat flow. The sweet spot at two-thirds thickness optimizes this property, ensuring efficient heat dissipation without risking damage to the pad or the components it’s cooling.

In summary, compressing soft silicone thermal pads to at least two-thirds of their original thickness ensures they perform as intended, providing reliable thermal management by enhancing contact, optimizing density, and minimizing resistance.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com