Thermal pads are used in specific scenarios where their unique properties offer advantages over thermal paste. Thermal pads excel in scenarios prioritizing ease of use, durability, insulation, and mechanical flexibility.

When components have irregular or uneven surfaces, thermal pads compress to fill larger gaps (typically 0.25~12 mm), ensuring consistent heat transfer without the risk of air pockets.

In environments where electrical conductivity is a risk, non-conductive thermal pads prevent short circuits, unlike some metal-based thermal pastes.

Ideal for quick assembly or mass production, as pads can be pre-cut and applied without the mess or precision required for thermal paste.

Suitable for sealed or hard-to-access devices (e.g., laptops, industrial equipment), as pads don’t dry out or degrade as easily over time.

When components cannot withstand high mounting pressure, pads require less compressive force to achieve contact compared to paste.

Helpful in prototyping or testing phases, as pads can often be reused if undamaged after disassembly.

In high-vibration environments (e.g., automotive electronics), pads stay intact better than paste, which might shift or pump out.

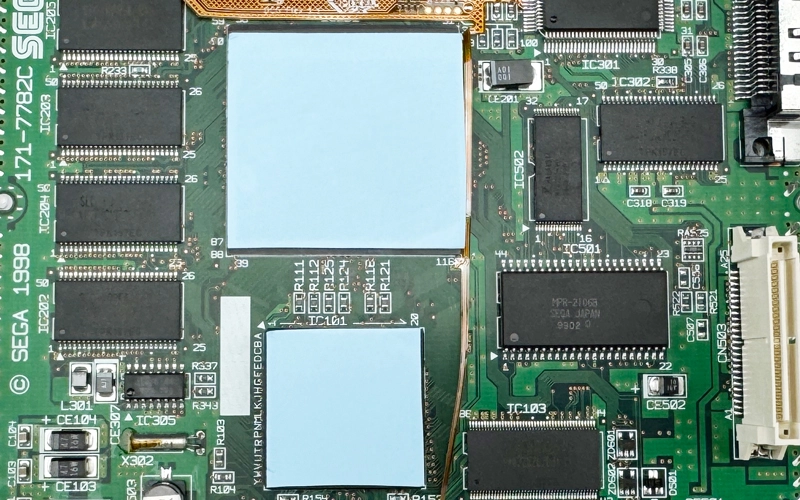

Useful for cooling multiple components on a PCB with uneven heights, as pads compress to accommodate differences.

Common in smartphones, tablets, and pre-built systems where user maintenance is unlikely, and reliability is key.

For applications where extreme heat dissipation isn’t critical, mid-range conductivity pads suffice, though high-performance pads (6~15 W/m.K) can bridge some gaps.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com