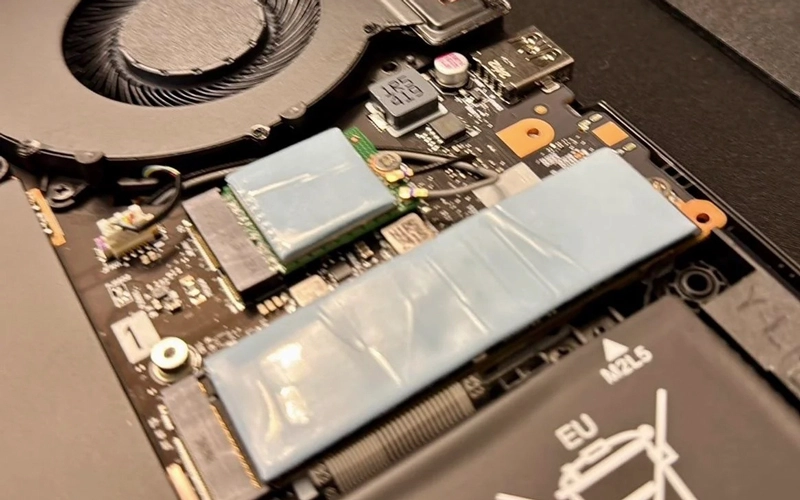

Thermal pads are essential for efficient heat transfer in electronic devices. However, some silicone-based thermal pads can experience oil migration, where oils seep out over time, potentially contaminating nearby components and affecting performance. This issue is particularly concerning in high-performance applications where oil contamination can impact both thermal conductivity and the longevity of the material.

To address this, manufacturers have developed thermal gap pads with low oil-bleed and low oil migration properties. For instance, AOK introduced the 'TP400 Series Thermal Pad,' which offers a typical thermal conductivity of 4W/mK and a Shore 00 hardness of 60. This pad is designed to minimize oil migration, making it ideal for applications where the appearance or production issues of silicone oils are undesirable.

Additionally, research has identified that oil bleed in elastomeric thermal silicone conductive pads is primarily due to uncrosslinked silicones in the cured resins, including unreacted silicone materials and macromolecular substances produced by the hydrosilylation reaction. Cured resins with a high crosslinking density and a high molecular weight of vinyl silicone residues exhibit a lower amount of oil bleed.

In summary, while oil migration from thermal pads can be frustrating, advancements in material science have led to the development of thermal gap pads with low oil-bleed and low oil migration properties, offering effective thermal management solutions for modern electronic applications.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com