Thermal paste and thermal gel are both types of Thermal Interface Materials (TIMs) used to enhance the thermal conductivity between two surfaces, typically between a heat source (like a CPU or GPU) and a heat sink. While they both serve the same primary purpose of improving heat dissipation, there are some differences in their composition, application, and performance characteristics.

Generally composed of a mixture of metal oxides, nitrides, or carbides suspended in a base material (which might be silicone or non-silicone). The metal particles, such as silver, aluminum, or zinc oxide, are responsible for the thermal conductive properties. Thermal pastes can vary significantly in terms of their specific formulations and thermal conductivity.

Often provides higher thermal conductivity compared to thermal gels, especially if it contains a high amount of metallic particles. It can more precisely fill microscopic imperfections on surfaces, ensuring better contact and heat transfer. However, the performance highly depends on the correct application.

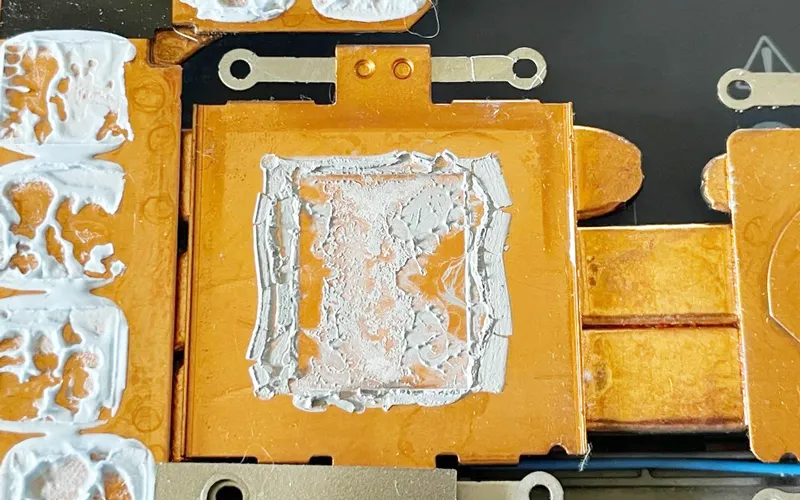

It requires manual application and usually comes in tubes. Applying thermal paste correctly is crucial for optimal performance, involving putting a small amount on the heat source and spreading it thinly and evenly or allowing the pressure from the heat sink to spread it. There's a bit of a learning curve to achieve the right application thickness.

Over time, it may dry out or pump out (squeeze out from between contacting surfaces), necessitating reapplication to maintain optimal thermal performance.

Can refer to two types of products: one is a gel-like TIM that combines properties of thermal pastes and adhesive gels, offering a consistency that's easier to apply for some users. Another interpretation of thermal gel is a pre-cured, gel-like pad that can be placed directly between the heat source and the sink. These pads often consist of a silicone material filled with a conductive agent (like a metal or ceramic powder).

Thermal Gel (liquid gel type): Like thermal paste, it's applied between the CPU and the heat sink but might offer an easier application due to its gel consistency, which can be less prone to creating air bubbles. Thermal Gel (Pad type), conversely, is more user-friendly, especially for beginners or in mass-production contexts, as it involves simply placing the pad on the component without worrying about spreading or quantity.

The performance of gel-like TIMs might slightly trail behind that of high-grade thermal pastes, particularly in high-performance or overclocking scenarios. Gel pads offer a compromise between ease of use and thermal performance, being more suitable for less thermally demanding applications or where consistency in application across many units is needed.

Gel pads are less prone to drying out compared to thermal paste but may offer slightly lower thermal conductivity. Liquid thermal gels may share similar maintenance needs to thermal paste depending on their formulation.

In general, the choice between thermal paste and thermal gel depends on the specific requirements of the application, including the desired balance between ease of use, thermal performance, and maintenance.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com