Selecting the best thermal pad for your application involves understanding several factors, particularly your specific use case. Here's a step-by-step guide to help you choose the right thermal pad:

Key Factor: This is the ability of the thermal pad to transfer heat from the heat source to a heatsink or other thermal management component.

Units: Thermal conductivity is measured in watts per meter Kelvin (W/m·K). The higher the value, the better the pad conducts heat.

Typical Range: Thermal pads can have values from 1 W/m·K to more than 15 W/m·K.

Consideration: For high-power electronics (e.g., automotive power electronics or CPUs), opt for pads with higher thermal conductivity (≥ 5 W/m·K).

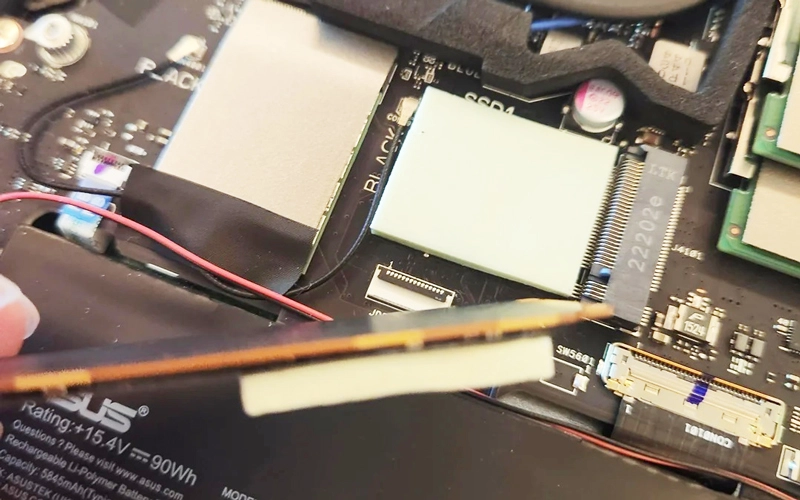

Key Factor: The thickness of the thermal pad is critical for filling gaps between components and the heatsink.

Consideration: If you have large gaps to fill, a thicker thermal pad (up to 5 mm) may be needed. For tight spaces, a thinner pad (below 1 mm) is more appropriate.

Effect on Performance: Thicker pads tend to have lower thermal conductivity, so there's often a trade-off between thickness and thermal performance.

Key Factor: This defines how easily the pad conforms to the surfaces it's applied to.

Shore Hardness Scale: Lower shore hardness means the pad is softer and can conform better to uneven surfaces. For delicate components, you may need a softer, more compressible pad.

Consideration: In automotive applications, vibration and varying mechanical stresses might require a balance between softness for surface conformity and enough firmness to resist deformation over time.

Key Factor: The pad should withstand the operating temperatures of your application.

Typical Range: Most thermal pads operate between -40°C to 200°C.

Consideration: For automotive electronics, especially near engines or power systems, you may need pads that can endure higher temperatures.

Key Factor: Some thermal pads also provide electrical insulation, which is important in electronics where you need to avoid short circuits.

Consideration: If you need both heat dissipation and electrical insulation, look for thermal pads with high dielectric strength.

Key Factor: Consider the longevity of the material under specific environmental conditions like humidity, vibration, and chemical exposure.

Automotive Applications: In an automotive setting, durability against oil, chemicals, and vibrations is essential. Some pads may have resistance coatings to enhance lifespan in such conditions.

Key Factor: Trusted brands often provide detailed specifications, certifications, and even independent testing results, which can help verify the claims.

Consideration: For safety-critical applications like in automotive electronics, look for thermal pads that meet industry certifications like ISO or UL compliance.

Key Factor: While cost shouldn't be the only consideration, it's an important one, especially when dealing with high volumes.

Consideration: Higher thermal conductivity and specific material properties (e.g., silicone vs. graphite) may increase cost.

Key Factor: Some thermal pads are easier to apply or remove, which could be important in environments where maintenance or replacement is necessary.

The best thermal pad will depend on the thermal management requirements of your device and the environment in which it will operate. For high-performance applications like automotive electronics, focus on pads with high thermal conductivity, durability, appropriate thickness, and compliance with relevant standards.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com