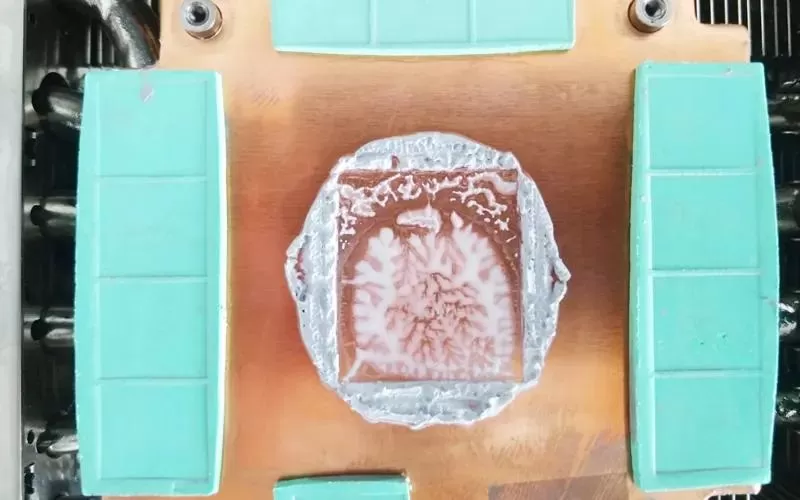

Good compression properties are critical to the selection and application of thermal interface materials. With proper compression, thermal interface materials can fill gaps, provide maximum thermal contact area, and reduce thermal resistance. This helps improve the efficiency and performance of the thermal solution, ensuring optimal heat transfer between the chip and heat sink.

The compressibility of thermal interface materials allows them to fill tiny gaps and uneven surfaces between the chip and heat sink. With proper compression, thermal interface materials can maximize the thermal contact area, thereby providing a better heat conduction path. This helps reduce thermal resistance and improve heat dissipation efficiency.

The presence of air gaps between the chip and the heat sink can lead to obstruction of heat transfer. Compressible thermal interface materials can fill these gaps and reduce or eliminate air layers, thereby lowering thermal resistance and improving thermal conductivity.

Chip and heat sink surfaces may have minor unevenness or bumps. Thermal interface materials with better compressibility can adapt to these surface features and fill gaps, ensuring more even contact and better heat transfer.

Good compressibility allows thermal interface materials to maintain their shape and performance under pressure. This is critical for long-term stable heat transfer, as temperature and mechanical stress can cause materials to deform or loosen in thermal solutions.

Therefore, selecting a thermal interface material with appropriate compressibility is critical to achieve good heat dissipation. In the application, by controlling the pressure and selecting the appropriate material thickness, the thermal interface material can be ensured to be fully compressed and form optimal thermal contact with the chip and heat sink, thereby maximizing heat dissipation performance.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com