What are Thermal Interface Material?

- Posted on:2022-09-23 17:08:00

- Source:AOK Thermal Pad Manufacturer FAQs

Thermal interface materials (TIMs) is a new type of industrial thermal material, used to dissipate and improve the transfer of heat out of electronics devices. Generally, they are placed between the heat-generating chip or component and the heat spreading substrate or dissipating device. These materials have been designed in recent years for the heat conduction requirements of equipment, and have excellent performance and reliability. They are suitable for various environments and requirements, have proper countermeasures for possible thermal conduction problems, and provide a strong help for the high integration of equipment, as well as ultra-small and ultra-thin. The thermal conduction products have been more and more applied to many electronic products, which improves the reliability of the product. There are several types of TIMs:

Thermal paste

Mostly used in the electronics industry, it provides a very thin bond line and therefore a very small thermal resistance. It has no mechanical strength (other than the surface tension of the paste and the resulting adhesive effect) and will need an external mechanical fixation mechanism. Because it does not cure, it is used only where the material can be contained or in thin application where the viscosity of the paste will allow it to stay in position during use.

Thermal adhesive

As with the thermal paste, it provides a very thin bond line, but provides some additional mechanical strength to the bond after curing. Thermal glue allows thicker bond line than the thermal paste, as it cures.

Thermal gap filler

It could be described as "curing thermal paste" or "non-adhesive thermal glue". It provides thicker bond lines than the thermal paste as it cures while still allowing an easy disassembly thanks to limited adhesiveness.

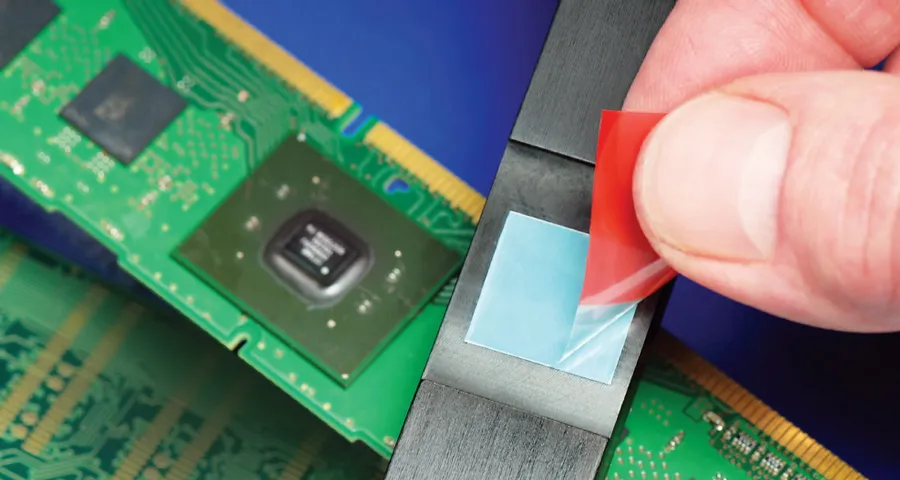

Thermally conductive pad

As opposed to previous TIM, a thermal pad does not come in liquid or paste form, but in a solid state (albeit often soft). Mostly made of silicone or silicone-like material, it has the advantage to be easy to apply. It provides thicker bond lines, but will usually need higher force to press the heat sink on the heat source so that the thermal pad conforms to the bonded surfaces.

Thermal tape

It adheres to surface, requires no curing time and is easy to apply. It is essentially a thermal pad with adhesive properties.

Phase-change materials (PCM)

Naturally sticky materials, used in place of thermal pastes. Its application is similar to solid pads. After achieving a melting point of - 55-60 degrees, it changes to a half liquid status and fills all gaps between the heat source and the heat sink.

Metal thermal interface materials (TIMs)

Metallic materials offer substantially higher thermal conductivity as well as the lowest thermal interface resistance. This high conductivity translates to less sensitivity to bondline thicknesses and coplanarity issues than polymeric TIMs.

In thermal design, it is often necessary to consider the heat conduction between the power device and the heat sink. Reasonable selection of heat transfer medium should not only consider its heat transfer capacity, but also take into account the process in production, maintenance operability, and excellent cost performance. TIMs are important for maintaining the performance and longevity of electronic devices by preventing overheating and reducing the risk of damage to the components.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.