How Thermally Conductive Gap Filler Pad Boosts Performance of Electronics

- Posted on:2022-09-30 11:13:00

- Source:AOK Thermal Pad Manufacturer FAQs

The thermally conductive gap filler pad is a thermal conductive material synthesized by a special process with silica gel as the base material, adding some metal oxides and other auxiliary materials. Thermally conductive gap filler pad is a heat dissipation product specially designed for heat transfer in the gaps of electronic products. It fills the gaps to transfer heat between the heat-generating parts and the heat-dissipating parts, and plays the role of insulation, shock absorption and sealing.

Why choose thermally conductive gap filler pad?

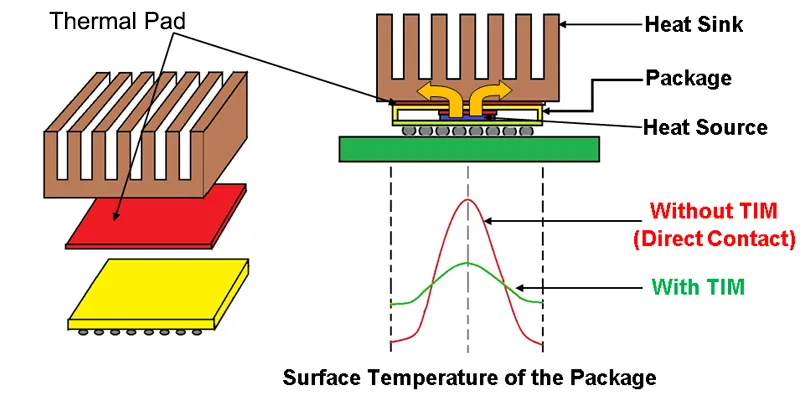

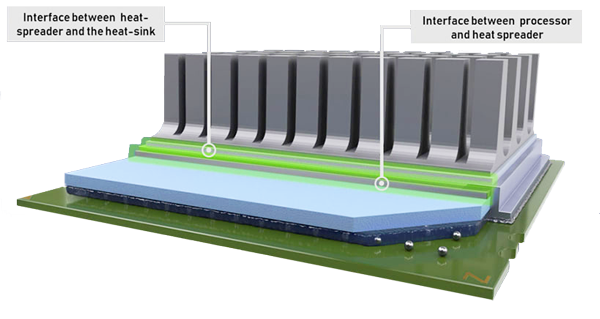

1. The main purpose of selecting thermally conductive gap filler pad is to reduce the contact thermal resistance generated between the surface of the heat source and the contact surface of the heat sink, and the thermal pad can fill the gap between the contact surfaces well;

2. Air is a poor conductor of heat, which will seriously hinder the transfer of heat between the contact surfaces, and installing a thermally conductive gap filler pad between the heat source and the radiator can squeeze the air out of the contact surface;

3. With the addition of thermally conductive gap filler pad, the contact surface between the heat source and the radiator can be better and fully contacted, and face-to-face contact can be truly achieved, so that the temperature response can be as small as possible.

Features:

• It has good elasticity and recovery, and can adapt to pressure changes and temperature fluctuations;

• It has appropriate flexibility and can fit well with the contact surface;

• Does not pollute the process medium;

• It has sufficient toughness without causing ring damage due to pressure and tightening force;

• No hardening at low temperature and small shrinkage;

• Good processing performance, convenient installation and pressing;

• The sealing surface is not bonded, and the disassembly is easy;

• Competitive cost and long service life.

Typical Applications:

• Between an IC and a heat sink or chassis; typical packages include BGAs, QFPs, SMT power components, and magnetics;

• Between a semiconductor and heat sink;

• Cooling for memory modules;

• In DDR and SD RAM assemblies;

• Cooling hard drives and computer parts;

• Thermal management of power supplies;

• In IGBT modules;

• Signal amplifier thermal management;

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.