Which Thermal Interface Material for Lightweight Battery Packs?

- Posted on:2022-09-05 10:37:00

- Source:AOK Thermal Pad Manufacturer FAQs

Lightweight thermal interface materials

Reducing weight is a major challenge for EV designers and manufacturers in their quest to reduce power consumption, but also to increase autonomy, which is today the biggest stumbling block for endc onsumer acceptance. There are, indeed, direct links between vehicle weight and energy consumption. You better have a lightweight battery pack if you want a long-lasting and performant battery. Thermal interface materials are an important part of the overall battery pack weight. Some solutions can better fit the requirements of engineers challenged on the weight of their battery packs.

Why striving for lightweight battery packs?

Let’s have a look at very simple figures: a 10% reduction in vehicle weight can result in a 6%~8% energy economy improvement. Replacing traditional steel and iron components with lightweight materials such as high-grade metals, alloys, carbon fibers, and polymer composites can directly reduce the weight of a vehicle’s body and chassis by up to 50% and, in turn for EV vehicles, reduce the battery weight they carry.

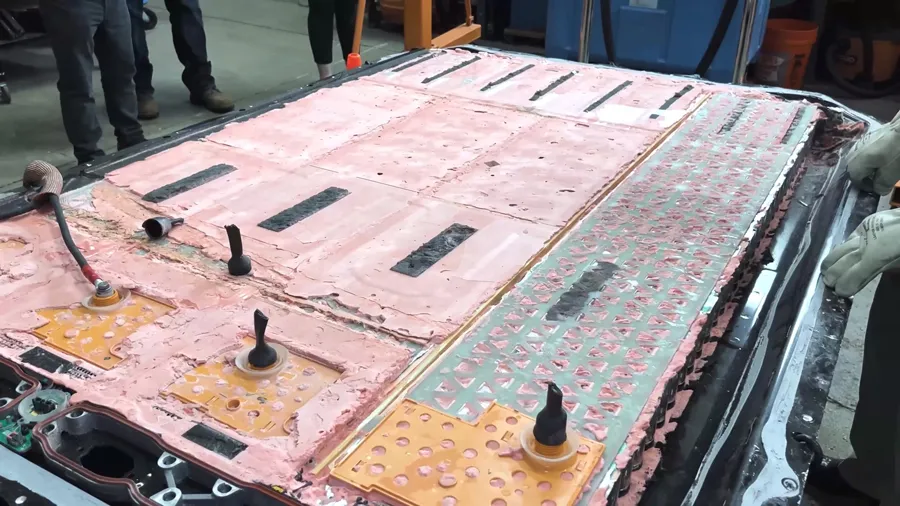

Battery packs usually weight 385~544 kg. This is a significant part of the overall vehicle weight. Considering thermal management activities usually look to fill any air gap with a material able either to conduct or stop the heat (thermal conductivity versus thermal insulation), you can easily imagine that thermal management is a critical process to look at to meet weight reduction challenges.

A few facts about electric car weight :

A Tesla Model X weight 2509kg, a battery pack usually vary 300~550kg depending on size and power we can roughly assume that a battery pack represent 20%~30% of the overall electric car weight. Tesla claims that the 4680 battery pack has 5 times more energy in a single cell, 16% more range for the entire vehicle, 6 times more power than a polar-ear battery, 6 times more power output, and higher density with only 950 cells and an energy density of about 330Wh/kg.

What kind of materials could lighten the overall thermal management system?

Thermal interface materials don’t have to be dense and heavy! It’s all about the thermal management system you will choose. The choice you will make between thermal conductivity and thermal insulation will determine your ability to work with lightweight thermal interface materials.

Thermally conductive materials are usually adhesives, and dense: do not expect to find the lightest solution if you’re looking for thermal conduction.

Thermal insulation solutions can be formulated as thermal gap fillers: they are lightweight thermal interface materials with very low density, the best option to lower the weight of your battery pack.

Thermal conductive gap filler are the highest-performance solution in the market today, combining best in class heat-resistance features with extremely low density, making it a solution of choice for any lightweight thermal insulation project, ensuring longer vehicle life and therefore becoming even more ecological and economical alternatives to traditional motor vehicles.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.