Use Thermal Interface Materials to Improve Thermal Conduction in Outdoor Power Supplies

- Posted on:2022-11-03 17:01:00

- Source:AOK Thermal Pad Manufacturer Industry News

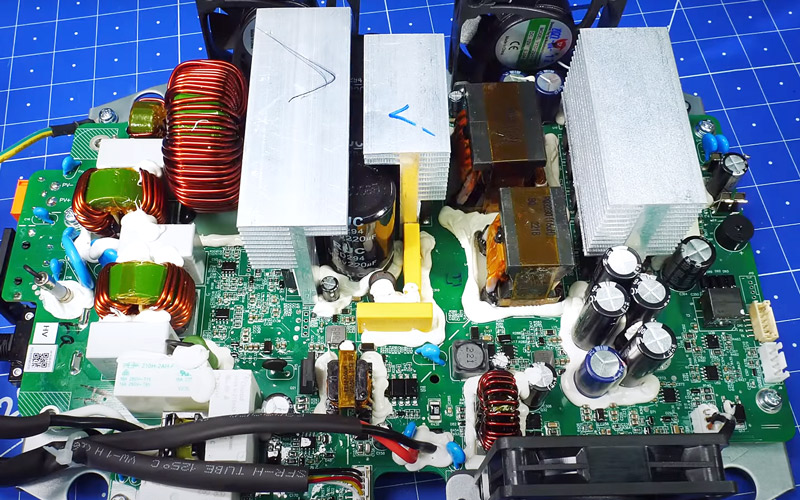

As a popular industry of energy storage power, outdoor power supply is also attracting more and more attention. Outdoor power supply is equivalent to a small portable charging station. It has the characteristics of light weight, large capacity, high power, long life and strong stability. It is not only equipped with multiple USB The interface can meet the charging of digital products, and can also output common power interfaces such as DC, AC, and car cigarette lighters. So what thermal interface materials are needed to dissipate heat from outdoor power supplies?

The common outdoor power supply is relatively large, and the long-term operation of the power supply cannot generate the heat normally dissipated, resulting in normal heat dissipation, and the power supply will heat up. If aging occurs, it will take a long time. Almost all devices have heat dissipation devices, and different layouts have different heat dissipation effects, so that the heat inside the power supply can be quickly transferred to the external heat dissipation interface, reducing the heat accumulation inside the power supply, so as to achieve the purpose of reducing the internal temperature.

The outdoor power supply is composed of a control board, a battery pack, an inverter and a BMS system, and the DC power is converted into an AC power through the inverter for use by other electrical appliances. At the same time, it also supports DC output of various interfaces to charge various digital devices. In the outdoor power supply, the thermal conductive materials are mainly used for the inverter part, the battery pack and the PCB. The inverter part is connected by thermal conductive gel, which can effectively reduce the contact thermal resistance and achieve better heat dissipation effect. When the battery is charged and discharged, the heat generated is very large, so the thermal conductive silicone pad is covered on the battery pack, and the thermal conductive silicone pad is also used on the PCB to transfer the heat to the casing. This dual-effect heat dissipation method enables the power supply to achieve better results during operation and prolong the service life of the power supply.

Thermally conductive gel shows good adaptability when used. It can adapt to various climates and can work normally at high and low temperatures. It can work in various low-temperature environments for a long time without damage. The surface affinity of the gel is very good, so that its hardness is very small, it shows strong plasticity, it can fill materials of various shapes, and it can compress the thickness very low, so that its heat transfer coefficient is very high. Low, its insulation is very good, and its many characteristics make it better to meet various needs.

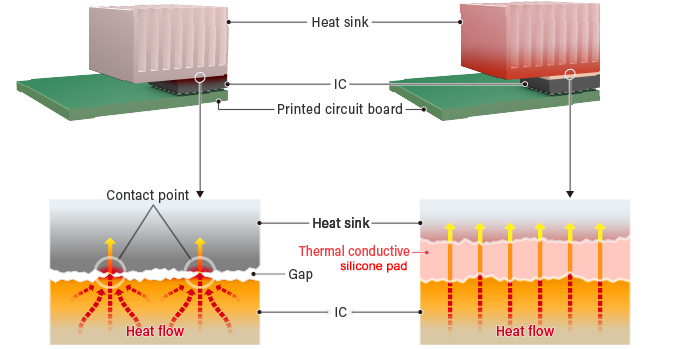

The thermal conductive silicone pad material is soft, the compression performance is good, the thermal conductivity and insulation performance is good, the thickness of the adjustable range is relatively large, suitable for filling the cavity, with natural viscosity on both sides, strong operability and maintainability, the main purpose of selecting the thermal conductive silicone pad It is to reduce the contact thermal resistance between the surface of the heat source and the contact surface of the heat sink, and the thermally conductive silicone pad can well fill the gap between the contact surfaces, because air is a poor conductor of heat, it will seriously hinder the transfer of heat between the contact surfaces. The addition of a thermally conductive silicone pad between the heat source and the radiator can squeeze the air out of the contact surface, with the addition of the thermally conductive silicone pad, the contact surface between the heat source and the radiator can be better and fully contacted. To face-to-face contact.

The temperature response can reach as small a temperature difference as possible, the thermal conductivity of the thermally conductive silicone pad is adjustable, and the thermal conductivity is better, The thermal conductive silicone pad has insulating properties (this feature needs to be added with suitable materials during production), the thermal conductive silicone pad has the effect of shock absorption and sound absorption, the thermal conductive silicone pad has installation, testing, and can be reused convenience.

Thermal interface material refers to a thermally conductive material inserted between components to efficiently dissipate the heat generated inside electronic devices. It is generally inserted between a heat-generating element such as an integrated circuit (IC) and a heat-dissipating component such as a heat spreader or heat sink.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.