With the continuous increase of the integration density and power density of electronic appliances, the rise of high-power LEDs, etc., electronic devices will release a lot of heat when they are working. Poor thermal conductivity will cause the temperature of the electrical working environment to rise sharply, affecting the operation stability of electronic devices. It even causes damage to the components. If no positive measures are taken, they will be "burned out" by the excess heat released by themselves in minutes. It is said that the reliability of electronic components will drop by 10% for every 2°C increase in temperature.

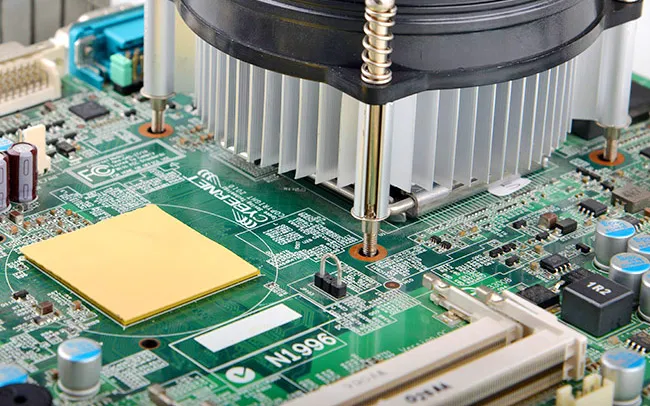

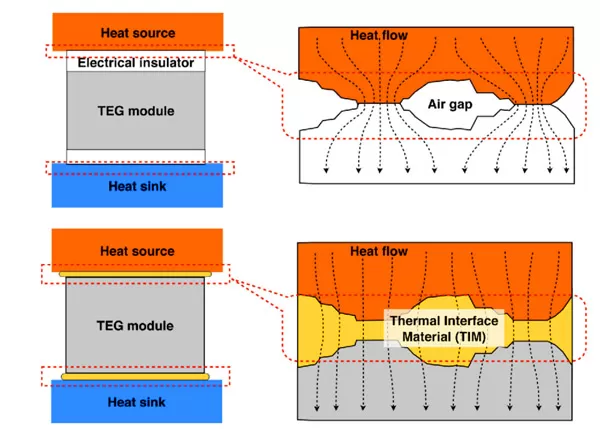

Thermal Interface Materials (TIM) is a filler used between two materials and is an important bridge for heat transfer. When two materials are joined to each other, whether it is the same material or two different materials, even if the surface of the material is very flat or a large fastening pressure is applied, it is still impossible to achieve close contact, only partial contact, and the middle must be fixed. There are still many fine voids or holes.

The air in the gap is a heat transfer medium with poor thermal conductivity, which will hinder the path of heat conduction and increase thermal resistance. Therefore, it is necessary to fill a thermal interface material between the two bonding materials to fill the gap, improve heat transfer efficiency, and reduce thermal resistance. It is a widely used and very important material.

Thermal interface materials are mainly used to fill the gap between the contact surfaces of two materials and reduce thermal resistance. Therefore, the thermal conductivity K is one of the important characteristics for evaluating thermal interface materials. The thermal interface material should have the following basic characteristics: compressibility and softness, high thermal conductivity, low thermal damping, surface wettability, good thermal cycle stability and so on.

The different characteristics and development of TIM can be simply divided into several categories: thermal paste, elastic thermal cloth, phase change thermal adhesive, thermal gel, thermal adhesive and thermal tape.

Thermal paste is a traditional heat dissipation material, viscous liquid with strong viscosity. Generally, it is used under a pressure of 100 ~ 400Pa, and its interface thermal resistance is about 0.2 ~ 1.0 K·cm²/W. The main components of the substrate are silicone oil and non-silicon polymers. The thermally conductive fillers are generally AIN and ZnO, and ceramic powders such as BN, Al2O3 or SiC or aluminum powder, silver powder, graphite powder, or even diamond powder can also be used. etc. to increase its thermal conductivity. But special attention should be paid to the dispersion of these fillers in the substrate and the viscosity control after mixing.

Since thermal paste does not need to be cured and is a liquid material, it can be added with a higher volume ratio of fillers, and its thermal conductivity is higher than other thermal interface materials. The thermal conductivity of the currently commercially available thermal paste is usually between 2 ~ 6W/m.K, and the best can be greater than 8W/m·K, and the thermal resistance is about 0.2 ~ 0.6W/m·K. The thermal paste itself has a certain fluidity and does not require too high a fastening pressure. After compression, its joint thickness can become quite thin, which is of great help in reducing thermal resistance. But the disadvantage is that it is prone to overflow and phase separation problems.

Elastic thermal conductive cloth is a kind of heat dissipation material derived from thermal conductive paste. Generally, it is mainly composed of various thermal conductive powders (such as BN, Al2O3, etc.) added to polysiloxane rubber compounds, and glass fiber cloth. The carrier forms a solid form which is easy to handle. The processing operation is relatively simple, and it is generally used under a pressure of about 700KPa, and its interface thermal resistance is about 1.0-3.0K*cm²/W. Elastic thermal conductive cloth can be used in the thermal management assembly technology of standard TO type transistors.

Phase-change thermally conductive materials can be organic materials or metal alloys. Phase-change thermally conductive materials combine the dual advantages of thermally conductive adhesive and thermally conductive grease. Before reaching the phase change temperature, its characteristics are similar to thermally conductive adhesives and have a certain degree of viscosity, so pumpout problems will not occur during crimping. When the temperature of the electronic device continues to rise to the melting point of the material, PCMs undergoes a phase change and becomes liquid, which has the same ability to fill the void as thermal grease, and thus greatly reduces the thermal resistance. At present, phase-change thermally conductive materials are mainly used as CPU cooling materials.

As far as organic phase change thermally conductive materials are concerned, phase change thermally conductive adhesives are mainly based on thermoplastic polymers, such as polyolefins, low molecular weight polyethylene and acrylic resins, added with low melting point solid paraffin, and added with high thermal conductivity fillers. Among them, paraffin is the main material undergoing phase change, and the temperature of phase change is generally controlled at 45 ~ 60°C. The current thermal conductivity of organic phase change materials is generally in the range of 1 ~ 3W/m.K.

Thermally conductive gels are generally composed of silicone oil and paraffin wax with thermally conductive fillers such as aluminum powder, aluminum oxide, and silver powder, and usually need to be cured. Because of the hinged treatment, it has strong internal cohesion properties and requires no heating or condensation when used. It can provide a more effective heat transfer path than thermal adhesives and adhesives, and its thermal conductivity is about 1 ~ 12W/m.K. The advantage of thermally conductive gels is that they can conform to the irregularities of the contact surface and fill the pores. In addition, due to its strong internal cohesion, there will be no overflow and movement problems during use, and it is very convenient to use and handle. Its disadvantage is that it needs to be cured.

Thermally conductive adhesive is an earlier product, and its main components are resin matrix, thermally conductive filler, diluent solvent or reactive diluent, curing agent and additives. The resin matrix used for electronic adhesives mainly includes: epoxy resin, polyimide, silicone, polyurethane, acrylate and cyanate, etc.

The development of conductive tape is mainly for heat sink HeatSink bonding material. The main purpose is to cancel the external force clamping device and reduce equipment cost. Conductive tape is mainly formed by coating pressure-sensitive adhesive with heat-conducting powder on a supporting material (such as glass cloth, polyimide film or aluminum foil). Thermally conductive tape is a type of pressure-sensitive adhesive and is easy to use. The use of conductive tape is very convenient, and it is attached in the same way as ordinary adhesive tape. Generally speaking, the heat conduction tape is mainly used for its viscous performance, followed by its heat dissipation performance, and it can only be applied to the interface with a flat surface.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.