Please accept our cookies to get the best experience of our website.

By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Why Don't More People Use Silicone Thermal Pads Instead of Thermal Paste?

- Posted on:2025-03-07 11:12:00

- Source:AOK Thermal Pad Manufacturer FAQs

Silicone thermal pads and thermal paste both serve the same purpose—improving heat transfer between components—but their distinct characteristics make them suitable for different applications. Here’s why thermal paste remains more widely used despite the advantages of silicone thermal pads:

Advantages of Silicone Thermal Pads:

- Ease of Use: No mess, no curing time, and no risk of over- or under-application.

- Reusability: Can be reused and repositioned multiple times.

- Uniform Thickness: Provides a consistent thermal interface without air gaps.

- Electrical Insulation: Reduces short-circuit risks.

- Durability: Resists drying or pump-out effects over time, unlike some pastes.

Why Thermal Paste is Still Preferred

- Higher Thermal Conductivity: High-quality thermal pastes typically achieve 8-15 W/(m·K) or higher, outperforming most silicone thermal pads (1-8 W/(m·K)). This makes paste ideal for CPUs, GPUs, and other high-performance applications.

- Superior Surface Conformity: Paste fills microscopic gaps and surface irregularities more effectively, minimizing thermal resistance. Pads may leave gaps on uneven surfaces.

- Efficacy on Small Contact Areas: Paste spreads more efficiently on components with precise contact points (e.g., chips), while pads excel on larger surfaces like MOSFETs or automotive electronics requiring mechanical reliability.

- Cost Efficiency: High-performance thermal pads are often 3-5× more expensive than thermal paste. Though reusable, pads may not justify the cost in consumer applications.

- Compression Precision: Pads require optimal thickness and compression for efficiency. Improper installation can degrade performance, whereas paste naturally forms an ideal thin layer under pressure.

When to Use Silicone Thermal Pads?

- Automotive electronics (vibration resistance and reliability critical)

- Applications demanding mess-free installation

- Scenarios requiring electrical insulation

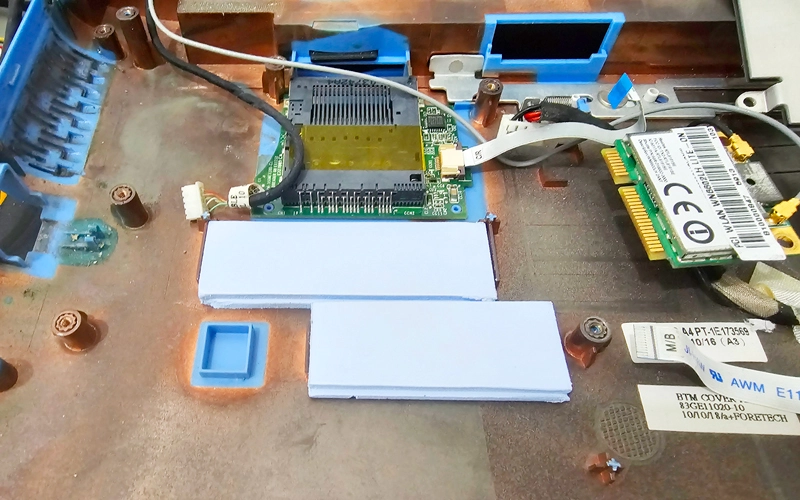

- Large components (e.g., VRMs, memory modules, power electronics)

Conclusion

While silicone thermal pads offer convenience and reliability, thermal paste dominates high-performance computing due to its superior thermal conductivity and adaptability. However, in industrial/automotive contexts (as in your case), thermal pads are often preferred for their long-term durability and ease of maintenance.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com

Updated on:2025-03-07 14:02:09