Both thermal paste and thermal pads serve the purpose of reducing and dissipating heat, but they have different characteristics and are suitable for different applications.

Thermal paste is a viscous, paste-like substance that fills the microscopic gaps between the heat source (such as a CPU or GPU) and the heat sink (such as a cooling fan or heat pipe).

It offers excellent thermal conductivity, allowing efficient transfer of heat from the heat source to the heat sink. Thermal paste can conform to irregular surfaces, ensuring better contact and heat transfer.

It's generally recommended for applications where there are uneven or non-flat surfaces, or when a thin and uniform layer of thermal interface material is required. Thermal paste may require reapplication after a certain period of time due to drying out or degradation.

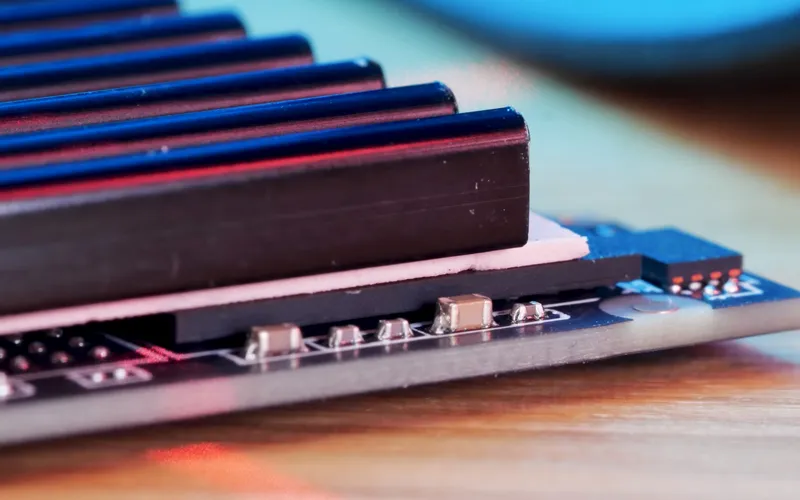

Thermal pads are pre-cut pads made of soft, pliable material with embedded thermally conductive fillers. They provide a convenient and easy-to-use solution as they come in standardized thicknesses and shapes. Thermal pads are non-messy and do not require curing time like thermal paste.

They offer good thermal conductivity, although generally lower than that of thermal paste. Thermal pads are suitable for applications with larger gaps or uneven surfaces, where conformability is less critical. They can be more durable and have a longer lifespan than thermal paste as they are less prone to drying out or degradation.

In summary, thermal paste is typically preferred for applications where precise contact and maximum heat transfer are crucial, especially on uneven or non-flat surfaces. On the other hand, thermal pads are a convenient option for applications with larger gaps or less critical contact requirements.

The choice between thermal paste and thermal pads depends on factors such as the specific components being cooled, the surface conditions, the required thermal conductivity, ease of application, and personal preference. It's recommended to consult the thermal material manufacturer's guidelines and consider the specific requirements of the application before deciding which one to use.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com