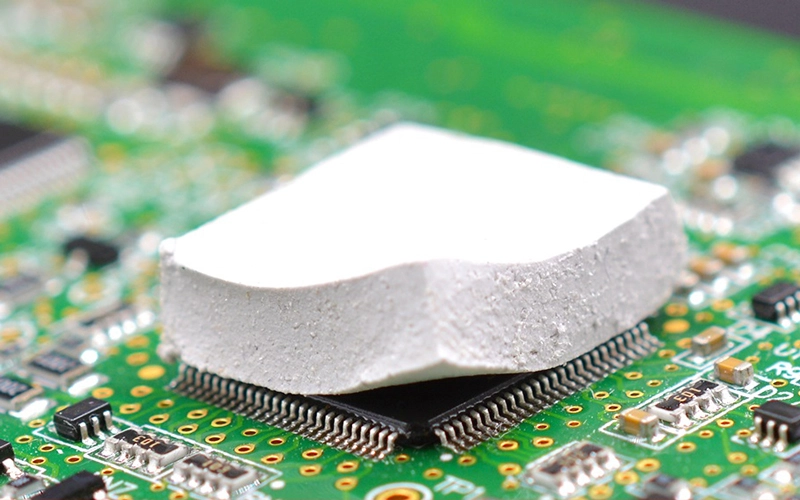

A thermal gap pad with low oil-bleed and low oil migration is typically designed to address concerns in high-performance applications where oil contamination can affect both thermal conductivity and the longevity of the material. This type of gap pad is often used in situations where there's concern about oil or other fluids interfering with the pad’s properties, such as in automotive, industrial, or power electronics.

This refers to the thermal pad's ability to resist releasing oils or other liquids over time, especially when exposed to heat. Pads with low oil bleed are more stable in high-temperature environments, ensuring that they maintain their thermal conductivity and do not degrade or interfere with surrounding components.

Migration refers to the tendency of oils to move from the pad into the surrounding area, potentially contaminating other components, leading to poor performance or reliability issues. Pads designed with low oil migration properties ensure that the oil stays within the pad and doesn't migrate, preventing damage to sensitive electronics.

Silicone-based Pads: These typically have better oil resistance, as they contain less volatile compounds, but care must be taken in choosing formulations that do not "bleed" oil over time. Polymer or Elastomer-based Pads: These materials can also provide low oil migration and bleed properties, with added benefits of lower compressibility and higher durability.

Automotive Electronics: In areas where engine or transmission heat may cause thermal pads to be exposed to oil or other fluids, using a thermal gap pad with these properties is critical. Power Electronics & Industrial Equipment: In environments with high temperatures and possible exposure to oils or other fluids, these pads ensure efficient heat transfer without contaminating surrounding components.

Thermal interface material manufacturers may use a combination of cross-linking agents or specific filler materials to enhance oil resistance while maintaining a balance between thermal performance and physical properties.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com