How to Solve the Problem of Chip Package Heat Dissipation?

- Posted on:2023-06-01 09:38:00

- Source:AOK Thermal Pad Manufacturer FAQs

Heat dissipation is a critical consideration in chip package design to ensure the proper functioning and prevent damage due to excessive temperatures. Here are some common strategies to solve the problem of chip package heat dissipation:

Heat sinks: Heat sinks are commonly used to dissipate heat from chip packages. They are usually made of metal, such as aluminum or copper, and are designed with fins or other structures to increase the surface area for heat transfer. Heat sinks absorb heat from the chip and dissipate it into the surrounding air.

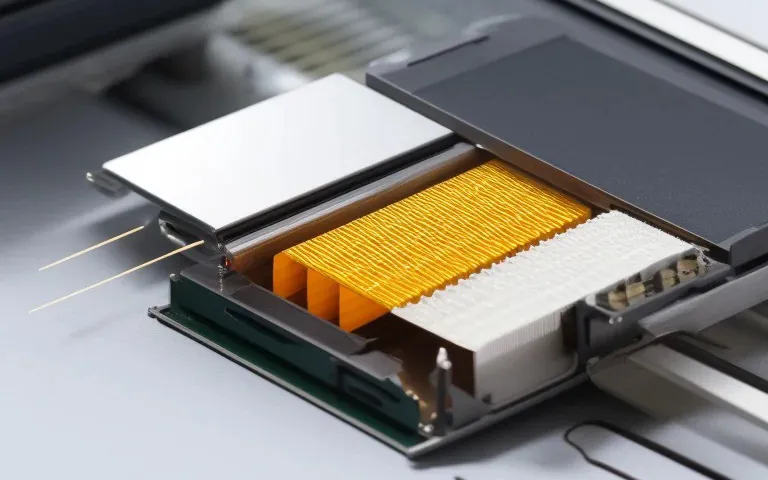

Thermal interface materials (TIMs): TIMs are used to improve the thermal conductivity between the chip and the heat sink. They fill in the microscopic gaps and air pockets between the chip and the heat sink, ensuring better heat transfer. Common TIMs include thermal greases,and thermal pads.

Thermal vias: Thermal vias are small holes in the chip package's substrate that allow heat to transfer from the chip to the printed circuit board (PCB) or other heat-spreading layers. These vias can improve heat dissipation by providing additional pathways for heat to escape from the chip.

Heat pipes: Heat pipes are highly efficient heat transfer devices that can be integrated into chip packages. They consist of a sealed copper pipe containing a small amount of working fluid. When the chip generates heat, the fluid evaporates, transfers heat to the cooler end of the pipe, condenses, and returns to the hot end, creating a continuous cycle that effectively dissipates heat.

Active cooling: In cases where passive cooling methods are insufficient, active cooling techniques can be employed. These include fans, blowers, or liquid cooling solutions. Fans and blowers circulate air around the chip package, enhancing heat dissipation. Liquid cooling uses coolant to absorb and remove heat, typically through a closed-loop system.

Efficient chip design: Optimizing the chip design can help reduce heat generation. Design considerations such as power management, circuit layout, and minimizing leakage currents can help decrease the overall heat output.

Adequate ventilation: Proper airflow and ventilation in the device or system housing the chip can help dissipate heat. Well-designed enclosures with vents or fans can facilitate the flow of cool air to the chip and remove hot air efficiently.

Thermal simulation and testing: Utilize thermal simulation software to model and analyze the heat dissipation characteristics of the chip package. Conducting thermal testing on prototypes can help validate the design and identify potential issues early on.

It's important to note that the specific solution for heat dissipation depends on factors such as the chip's power density, operating conditions, space constraints, and application requirements. Consulting with thermal engineers or experts in a chip package design can provide more tailored recommendations based on your specific situation.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.