How Do You Dissipate Heat in Electronics?

- Posted on:2023-02-17 10:45:00

- Source:AOK Thermal Pad Manufacturer FAQs

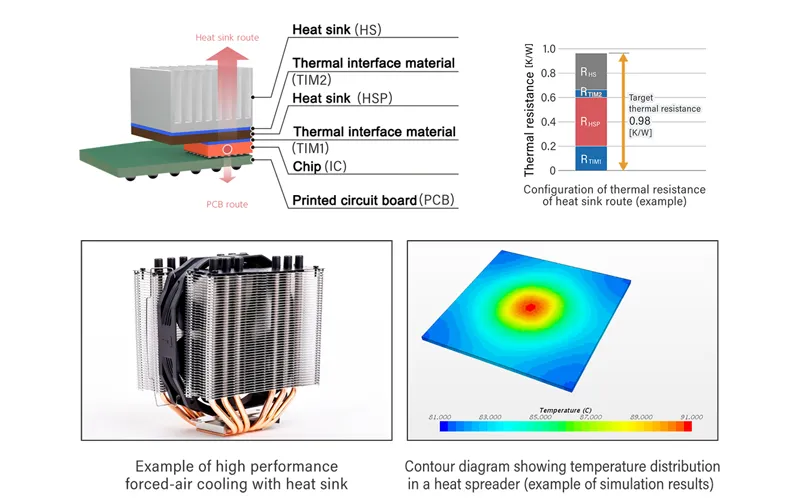

There are two main ways to dissipate heat for electronic products: one is to use heat sinks, and the other is to use fans to dissipate heat. A heat sink is a sheet of metal or other material that transfers heat from an electronic component to the air, thereby reducing the temperature of the electronic component. Fan cooling is to take heat away from electronic components by blowing air, thereby reducing the temperature of electronic components.

Heat dissipation design is an important part of electronic products. Its purpose is to release the generated heat from electronic components to prevent overheating and burnout of electronic components.

The basic principles of thermal design are:

1.Dissipate heat away from electronic components to prevent overheating and burning out electronic components.

2.By using a heat sink, the heat is transferred from the electronic components to the air so that it can be dissipated quickly.

3.By using a fan, the heat is transferred from the radiator to the air for quick dissipation.

4.By using heat pipes, the heat is transferred from the electronic components to the heat sink and air for quick dissipation.

The three most common materials used for dissipating heat in electronic products are thermal greases, thermal pads, and thermal tapes.

Thermal Grease

Thermal grease is the most widely-used and cost-effective of the thermal dissipation materials we’re examining. Grease is an extremely conductive material that is easy to apply to almost any product, usually coming from a tube. When applied to the entire surface of a product, it can be the most effective dissipating material around.

However, grease is messy. If maintenance needs to be done to the product later in its lifecycle, the messiness of grease can make it difficult. In addition, it can also be an inconsistent dissipator depending on the operator. If not applied to cover a component’s surface completely, it will not be effective in dissipating heat. Thermal grease also has a particular working temperature, meaning if used at too high a temperature, it can liquify and migrate. This will result in it being even less effective at dissipating heat.

Thermal grease is most commonly used in low-cost electronics, as well as any products with a controller, such as lawnmowers, leaf-blowers, or chainsaws. These products don’t see constant use and need a dissipating material that won’t degrade, making thermal grease the best choice.

Thermal Pads

Thermal pads are an incredibly consistent material for heat dissipation. Generally, these gap pads arrive in sheets and can be die-cut to fit electronic product components perfectly. They have a putty-like texture, are filled with conductive materials (such as ceramic), and can be thick or thin depending on the application. As the conductivity of the pad increases, the thicker the pad gets.

Thermal gap pads are also an expensive material to use for heat dissipation. Since they are a filled material, they increase in price as you try to cover more space with them. Likewise, the price increases as the conductivity level does.

Thermal pads are most commonly used in smartphones, computers, laptops, and products with high heat environments. Thermal gap pads provide devices with the dissipation they need without the risk of degrading or moving within the product. Pads also provide products in high heat environments the dissipation they require without risk of liquifying and becoming ineffective.

Thermal Tape

Thermal tape is more of a niche material for heat dissipation, meaning it’s only truly useful in certain situations. There are two types of tapes that can be used for dissipating heat: pressure-sensitive adhesives (PSAs) and certain types of pads that have high tack. Thermal tapes are most advantageous during the design phase of a product, as they can save time during assembly by eliminating the need to use screws for specific products.

However, thermal tapes are generally only suitable for electronic products with low conductivity, since the tapes themselves are not very conductive. This means they can usually be used on products that do not emit high levels of heat.

Thermal tapes are most commonly used with LED lighting strips, as well as other mounted appliances, since they have the highest tack and ability to hold components together.

Circuitry used in electronics heats up with use and becomes unstable if its temperature rises above 100°C to about 120°C. Therefore, it is very important to implement proper thermally conductive materials.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.