Why Are Thermal Pads Used in PCB Design and Manufacturing?

- Posted on:2023-06-14 15:08:00

- Source:AOK Thermal Pad Manufacturer FAQs

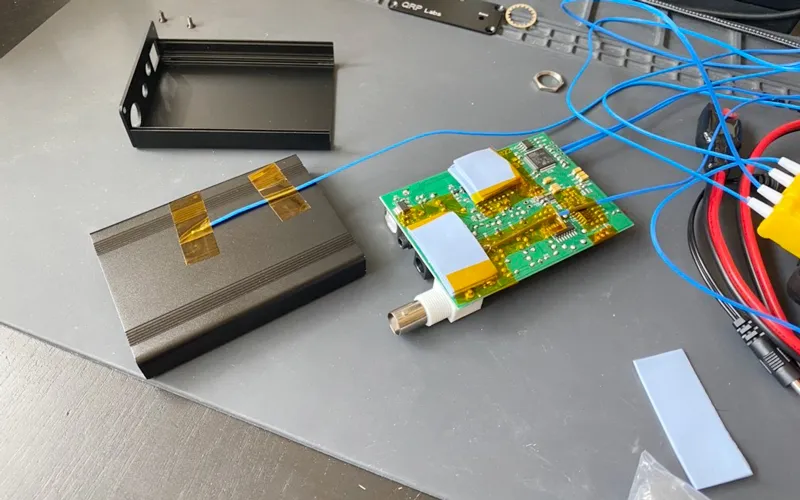

A thermal pad is a type of thermal material that is commonly used in printed circuit board (PCB) design to dissipate heat away from high-power components. Thermal pads are typically made of a thermally conductive material, such as silicone or graphite, and are placed between the component and the PCB to act as a heat sink. They can also be used to fill gaps between the component and the PCB to improve heat transfer.

Here are some of the key reasons why thermal pads are used in PCB design:

Temperature control: Electronic components on a PCB can generate significant amounts of heat during operation. Thermal pads help to dissipate this heat away from the components, ensuring they remain within their specified temperature range, which is essential for maintaining performance and reliability.

Thermal conductivity: Thermal pads are made of materials with high thermal conductivity, such as silicone, graphite, or other thermally conductive polymers. This property allows them to efficiently transfer heat between the heat-generating components and the heat sink or other cooling solutions.

Protection against thermal stress: Uneven temperature distribution across a PCB can lead to thermal stress, which can cause warping or damage to the board and its components. By effectively spreading and transferring heat, thermal pads help to reduce thermal stress and prevent potential issues.

Thermal interface materials (TIMs): Thermal pads serve as an interface between the heat-generating components and the heat sinks or other cooling solutions. They fill the microscopic air gaps between the two surfaces, ensuring optimal heat transfer and lower thermal resistance.

Electrical isolation: Some thermal pads also provide electrical isolation between the components and the heat sink or other cooling solutions, preventing short circuits or electrical interference.

Easy installation and maintenance: Thermal pads are generally easy to install and replace, as they don't require any adhesive or special tools. They can be cut to the required size and shape, making them suitable for various applications and PCB designs.

Thermal pads play a crucial role in PCB design and manufacturing by providing efficient heat transfer, reducing thermal stress, and ensuring the reliable operation of electronic components.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.