What Is the Optimal Thickness for a Thermal Cooling Pads?

- Posted on:2023-07-11 15:03:00

- Source:AOK Thermal Pad Manufacturer FAQs

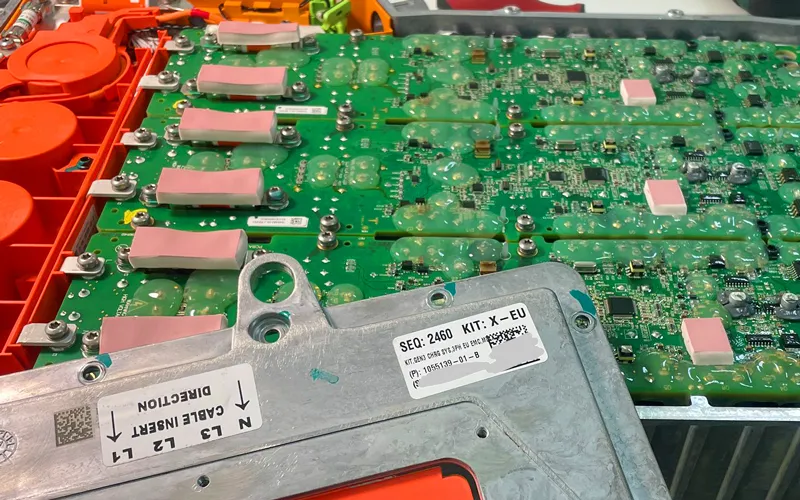

The optimal thickness for a thermal pad depends on several factors, including the size and shape of the component, the thermal conductivity of the pad material, and the thermal requirements of the application.

In general, a thermal pad should be thick enough to fill any gaps between the component and the heat sink or other cooling device, while still allowing for good mechanical contact between the two surfaces. Thermal cooling pad a thickness of 0.5 ~ 1.5mm is commonly used for many applications, but the optimal thickness can vary depending on the specific requirements of the application.

If the thermal pad is too thin, it may not provide adequate thermal conductivity and heat dissipation, which can result in higher operating temperatures and reduced component lifespan. If the pad is too thick, it can create excess thermal resistance and impede heat transfer, which can also lead to higher temperatures and reduced performance.

It's important to carefully evaluate the thermal requirements of the application and select a thermal pad with an appropriate thickness that will provide optimal thermal performance while maintaining good mechanical contact between the component and the cooling device. The manufacturer's specifications and guidelines should be consulted to determine the optimal thickness for a particular application.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com