What Are the Advantages of Using a Thermal Conductive Pad?

- Posted on:2023-12-04 16:08:00

- Source:AOK Thermal Pad Manufacturer FAQs

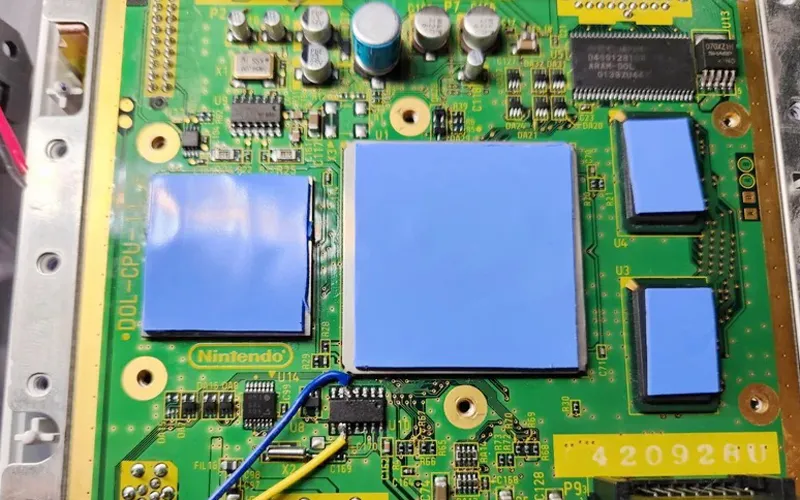

The use of thermal conductive pads offers several advantages in various applications where heat dissipation is critical, include efficient heat transfer, ease of application, electrical insulation, conformability, vibration absorption, reusability, temperature stability, and non-corrosiveness. These features make thermal conductive pads a preferred choice in various industries, including electronics, automotive, power systems, and more, where reliable heat dissipation is crucial.

Heat Transfer Efficiency: Thermal conductive pads are designed to have high thermal conductivity, which allows them to efficiently transfer heat from the heat source to a heat sink or other cooling mechanisms. They provide a direct thermal pathway, minimizing thermal resistance and promoting effective heat dissipation.

Easy Application: Thermal conductive pads are typically pre-cut or available in sheet form, making them easy to handle and apply. They can be conveniently placed between heat-generating components and heat sinks without the need for additional adhesives or complex installation processes. This simplifies the assembly and saves time during device manufacturing or maintenance.

Electrical Insulation: Many thermal conductive pads are electrically insulating, which means they prevent electrical conductivity between components. This feature is particularly important in electronic devices where there is a risk of short circuits or electrical interference. The insulating properties of thermal pads help ensure the safety and integrity of the system.

Compression and Conformability: Thermal conductive pads are often compressible, allowing them to conform to uneven or irregular surfaces. When pressure is applied, they fill gaps and imperfections, creating better contact and improving thermal conduction. This feature helps eliminate air gaps that can impede heat transfer and ensures uniform heat distribution across the interface.

Vibration and Shock Absorption: Some thermal conductive pads have additional properties, such as vibration damping or shock absorption. These pads help reduce the impact of mechanical vibrations or shocks on the components, providing added protection and enhancing the overall reliability of the system.

Reusability: Certain types of thermal conductive pads can be reused multiple times, which can be advantageous in scenarios where components need to be disassembled and reassembled. The ability to reuse thermal padsreduces material waste and can result in cost savings over time.

Temperature Stability: Thermal conductive pads are designed to withstand high temperatures and maintain their properties over a wide temperature range. They exhibit good thermal stability, ensuring effective heat dissipation even in demanding operating conditions.

Non-Corrosive: Thermal conductive pads are typically non-corrosive, meaning they do not degrade or react with the surfaces they come into contact with. This characteristic helps protect sensitive components and ensures the long-term integrity of the system.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com