The Key Role and Applications of PI Film in Thermal Interface Materials | Electronics Thermal Management

- Posted on:2025-09-12 09:49:00

- Source:AOK Thermal Pad Manufacturer FAQs

In an age where electronic devices are becoming increasingly precise and powerful, heat dissipation has emerged as a critical challenge for R&D engineers. Among the thermal interface materials we use daily, there's a crucial component that may not be widely known but plays a silent yet monumental role: polyimide film, commonly referred to as PI film.

Why is PI film so important? What unique value does it bring to thermal materials? Today, let's explore its significance.

1. Five Key Functions of PI Film in Thermal Pads

① Enhanced Electrical Insulation Protection: PI film has excellent dielectric strength and high volume resistivity. It effectively provides electrical isolation, preventing high-voltage breakdown or short circuits between heating components and heat sinks or enclosures. Especially in high-voltage applications like battery management systems and industrial inverters, PI film acts as a critical safety barrier for the entire thermal dissipation system.

Key Metrics:

- Volume Resistivity: >10¹¹ Ω·cm

- Breakdown Voltage: ≥5.0-6.0 kV/mm

② Improved Mechanical Performance: PI film boasts high mechanical strength, rigidity, and outstanding dimensional stability, which significantly enhance the thermal pad's compression resistance and anti-deformation capabilities. For ultra-thin pads less than 0.5mm thick, PI film improves tear resistance, making them less prone to damage during installation or removal. It also provides an effective structural skeleton for base materials like thermal silicone.

Performance Improvements:

- Tensile Strength: Increased by 2-15 times

- Tear Resistance: Significantly improved

- Dimensional Stability: Excellent

③ Supports Ultra-Thin Designs: PI film can be manufactured in extremely thin specifications, such as 12.5μm and 25μm. This allows thermal pads to be made thinner while maintaining mechanical and insulating properties, meeting the increasingly strict thickness requirements of consumer electronics and automotive electronics.

Advantages:

- Saves installation space

- Reduces thermal resistance

- Accommodates miniaturized electronic devices

④ High-Temperature Stability: PI film can withstand long-term exposure to temperatures above 200°C and has a very low coefficient of thermal expansion. In high-temperature environments, it doesn't easily soften, deform, or decompose. This helps maintain stable contact at the thermal interface, prevents an increase in thermal resistance, and ensures the reliability of heat dissipation for power electronics.

Temperature Performance:

- Continuous Operating Temp: Up to 200°C

- Low coefficient of thermal expansion

- Thermal Decomposition Temp: >500°C

⑤ Chemical Corrosion Resistance: PI film is resistant to most solvents and chemicals, allowing thermal pads to maintain their performance in humid or chemically corrosive environments and extending the material's service life under harsh conditions.

2. PI Film-Reinforced Thermal Pad Product Showcase

Here are some representative PI film-based thermal products with detailed specifications related to PI film:

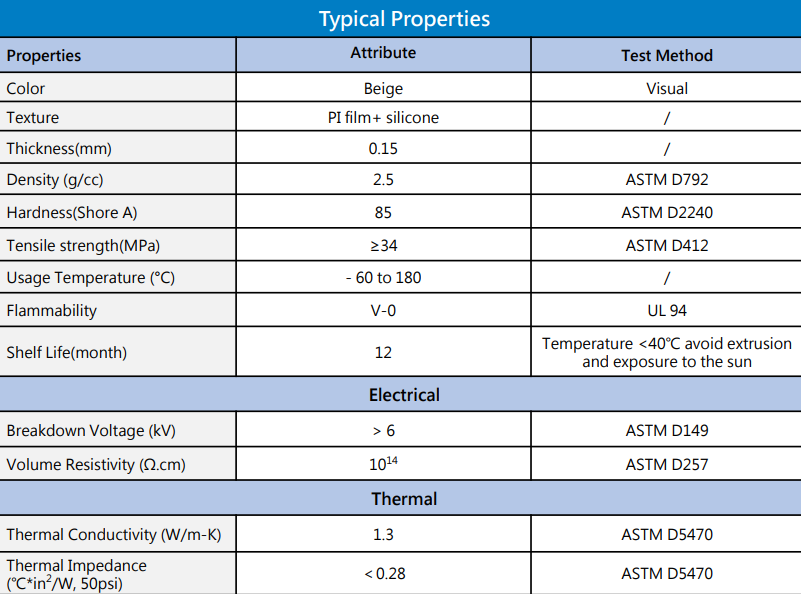

PI Film Thermal Insulating Pad TC-K10

TC-K10 Electrically Insulating Thermal Sheet is a high-performance, elastic insulating material based on a special film. It has excellent cut resistance and thermal conductivity and is widely used in the electronics and appliance industries. To use it, simply cut the thermal silicone pad to the required size based on the heating surface and gap height and place it in the gap between the heating surface and its component to act as a thermal interface medium.

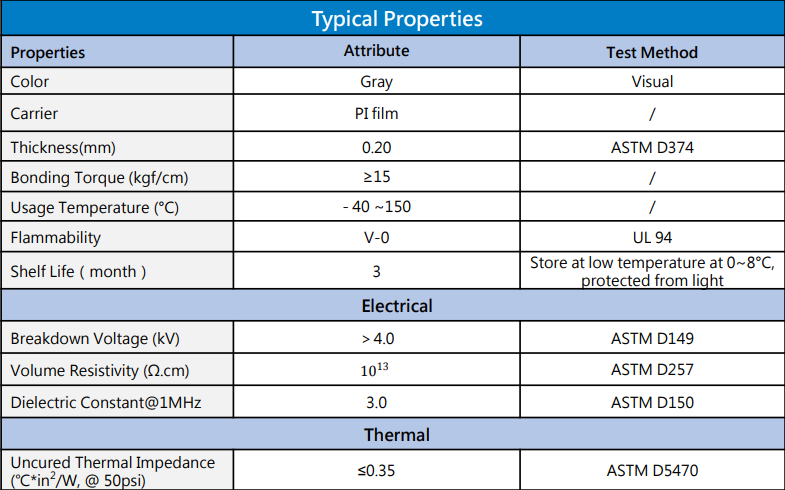

PI Film Thermosetting Thermal Insulating Tape TCK15B

TCK15B is a heat-cured thermal insulating tape. It consists of a high-performance, low-modulus thermal silicone resin compound coated on a carrier material with a double-layer protective liner. The low-modulus silicone is designed to effectively absorb mechanical stress caused by CTE mismatch, impacts, and vibrations while providing outstanding thermal performance (compared to double-sided tape) and long-term integrity. TCK15B is commonly used to structurally bond power components to heat sinks on PCBs.

PI Film-Reinforced Silicone Thermal Pad TP300-H35-PI

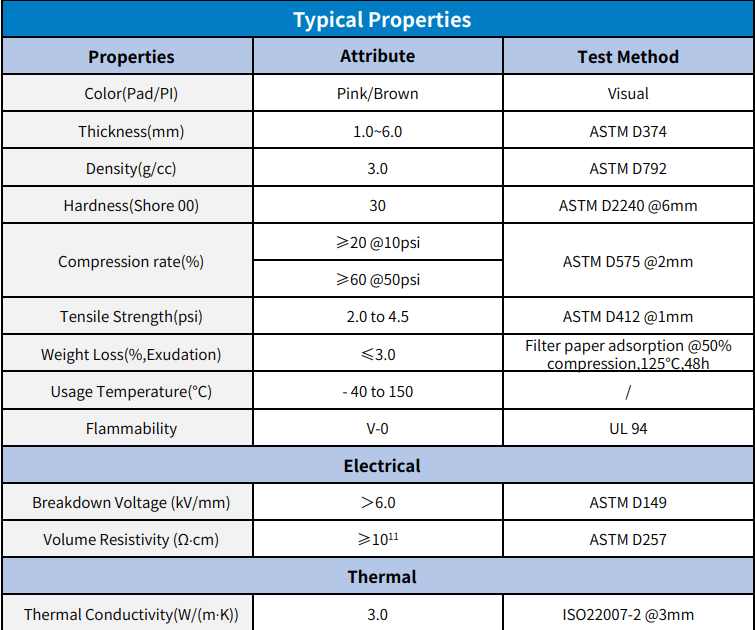

TP300-H35-PI is a 3.0 W/m·K Silicone Thermal Pad reinforced with PI film using a special process. It offers high electrical insulation, a wide range of applications, and stable operation in temperatures from -40℃ to 150℃. It also meets the UL 94 V-0 flame retardant rating.

PI Film Phase Change Thermal Material PCM160-MPI

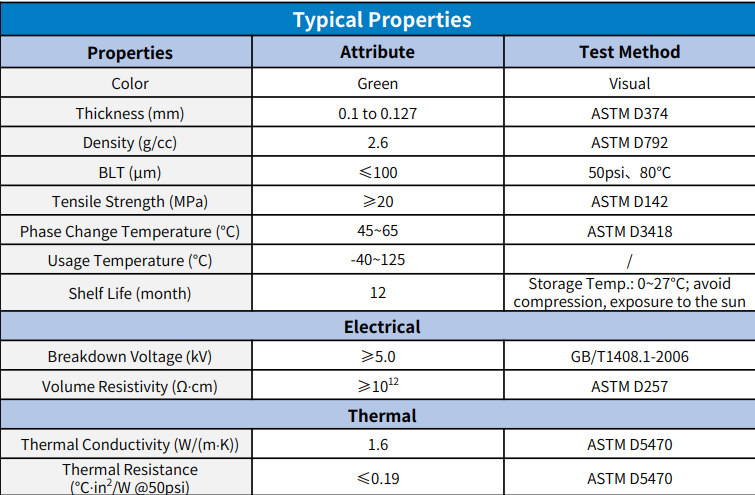

PCM160-MPI is a high-performance thermal phase change material with an intermediate layer of PI film and a phase change temperature of 45-65℃. At room temperature, the PCM series is a solid sheet, but it becomes a paste-like substance when it exceeds its phase change temperature. It offers excellent wettability and compressibility. The material can be cut into various sizes according to customer requirements and is applied between the heat sink and power-consuming electronic components. It fills the gaps between the heat source and heat sink to minimize thermal resistance.

3. Main Application Areas

- High-Voltage Applications - Electric vehicle battery systems, charging equipment, industrial inverters, etc., where PI film provides critical electrical isolation.

- High-Reliability Systems - Data center GPUs/CPUs, 5G equipment, and aerospace electronics, where PI film ensures long-term stable operation.

- Precision Manufacturing - Automated SMT mounting and precision assembly, where PI film enhances material handling and process adaptability.

- High-Temperature Environments - Automotive engine compartments and high-power devices, where PI film guarantees stable performance under extreme temperatures.

PI film, as a "diamond-level partner" for thermal pads, has become an indispensable core material in efficient heat dissipation systems due to its outstanding electrical insulation, mechanical reinforcement, and thermal stability. In this field, aok Technology continues to innovate, launching PI film-reinforced thermal materials like TCK15B, TP300-H35-PI, and PCM160-MPI. These products meet the demands for efficient heat dissipation across various industries with their high thermal conductivity, long service life, and excellent electrical and mechanical properties. As technology continues to advance, the importance of PI film in thermal management will become even more pronounced, driving electronic devices toward greater efficiency and miniaturization.