Graphene Thermal Pad vs Thermal Paste: Ultimate Heat Dissipation Guide 2025

- Posted on:2025-08-22 16:00:00

- Source:AOK Thermal Pad Manufacturer FAQs

With the continuous improvement of electronic device performance, heat dissipation has become a critical challenge. Particularly for high-power, high-density chips that generate substantial heat during operation, inadequate heat dissipation can significantly impact device performance and lifespan. Traditional thermal paste can no longer meet these demanding requirements, while graphene thermal pads, as an emerging technology, are becoming the "black technology" in the heat dissipation field. But how should one choose between graphene thermal pads and thermal paste? This article will provide an in-depth comparison of these two materials' advantages and disadvantages, helping you find the most suitable heat dissipation solution.

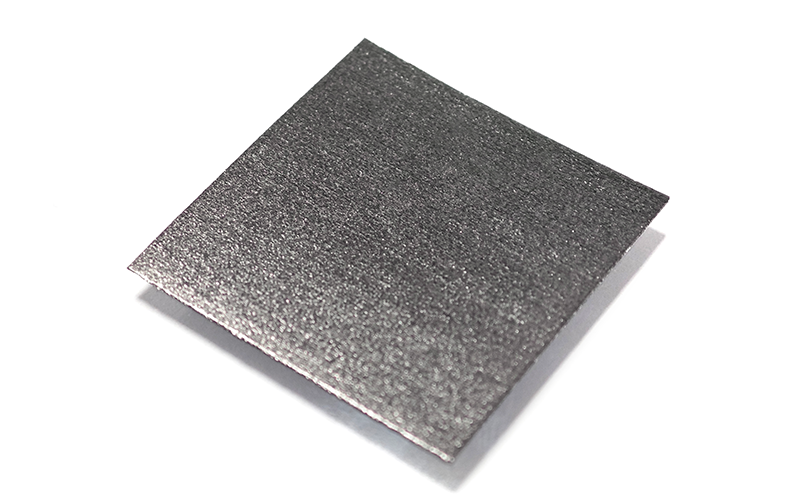

Core Advantages of Graphene Thermal Pads

The emergence of graphene thermal pads has addressed the shortcomings of traditional thermal materials in multiple aspects, particularly demonstrating stronger competitiveness in high-power, high-density devices. Through material innovation, they have enhanced thermal efficiency, flexible adaptability, long-term reliability, and environmental adaptability, making them an ideal choice for high-performance electronic device heat dissipation.

-

Ultra-High Thermal Efficiency

Graphene itself is a material with extremely high thermal conductivity, and graphene thermal pads fully utilize these characteristics. Compared to traditional thermal paste, graphene thermal pads have a thermal conductivity of up to 130 W/m·K, effectively conducting heat generated by chips to heat sinks rapidly and preventing heat accumulation. -

Long-Term Stability and Maintenance-Free Operation

Traditional thermal paste requires regular replacement, especially in high-temperature environments where it tends to evaporate or dry out, leading to decreased heat dissipation effectiveness. Graphene thermal pads have a service life of over 10 years, eliminating the hassle of frequent replacements. This long-term stability is particularly important for high-power devices. -

Multi-Scenario Application Adaptability

Graphene thermal pads are not only suitable for high-density, high-power scenarios, but their high and low temperature resistance and anti-aging properties enable them to work stably in extreme environments for extended periods. Whether for outdoor equipment, automotive electronics, or RF modules, graphene thermal pads can handle these applications with ease.

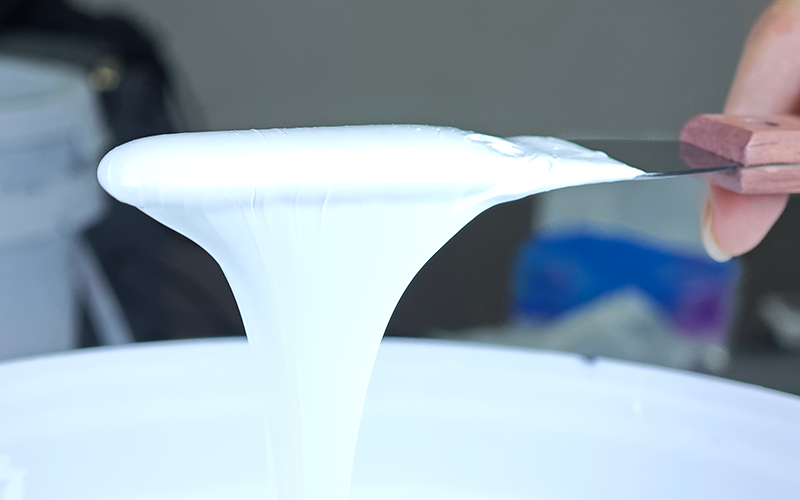

Advantages and Limitations of Thermal Paste

Although graphene thermal pads are gradually becoming leaders in the heat dissipation field, thermal paste still holds a place in certain scenarios. Let's examine the advantages and limitations of thermal paste.

- Advantages

- Ease of Use: Thermal paste is widely used in various devices, with simple application and flexible usage. For small devices or non-high-power devices, thermal paste remains a convenient and low-cost choice.

- Lower Initial Cost: Compared to graphene thermal pads, thermal paste is more affordable, making it the preferred choice for budget-conscious consumers.

- Limitations

- Lower Thermal Efficiency: Although some high-end thermal pastes can achieve thermal conductivity of 15 W/m·K, their heat dissipation effectiveness is far inferior to graphene thermal pads. In high-density, high-power devices, thermal paste cannot meet the demands of long-term high-load operation.

- Volatility and Aging: Thermal paste gradually evaporates at high temperatures and dries out after long-term use, leading to significantly reduced heat dissipation effectiveness. This characteristic requires users to replace it regularly, increasing maintenance costs.

- Uneven Application Issues: The heat dissipation effectiveness of thermal paste depends on application uniformity. Improper application increases thermal resistance, resulting in suboptimal heat dissipation performance.

Comparison Between Graphene Thermal Pads and Thermal Paste

-

Thermal Performance Comparison

Graphene thermal pads demonstrate superior heat dissipation performance compared to traditional thermal paste under most testing conditions, with particularly significant advantages in high heat generation scenarios. Under high-pressure environments, their performance improvement margin is also greater than thermal paste, proving the potential and value of graphene materials in thermal applications.

- Long-Term Reliability Comparison

- Graphene Thermal Pads: Service life can exceed 10 years, suitable for long-term stable operation, eliminating the hassle of frequent replacements.

- Thermal Paste: Requires replacement every 2-3 years and is prone to evaporation and drying in high-temperature environments, affecting long-term device usage.

- Application Scenarios

- Graphene Thermal Pads: Suitable for high-power, high-density devices, especially those requiring long-term maintenance-free operation, such as automotive electronics, new energy batteries, and RF modules.

-

Thermal Paste: Suitable for general consumer electronic devices or low-power devices with minimal heat dissipation requirements.

How to Choose the Right Heat Dissipation Solution?

- High-Power and High-Density Applications: For high-power devices that handle large amounts of heat, choosing graphene thermal pads will provide more efficient and stable heat dissipation effects.

- Long-Term Stable Operation Requirements: If devices need to operate long-term without frequent maintenance, the maintenance-free characteristics of graphene thermal pads make them an ideal choice.

- Budget-Limited or General Applications: If budget is limited and device heat dissipation requirements are low, thermal paste remains a cost-effective choice.

Choosing heat dissipation materials not only affects the long-term stable operation of devices but also impacts maintenance costs and performance. When dealing with high-power, high-density electronic devices, graphene thermal pads are gradually becoming the mainstream choice in the heat dissipation field due to their excellent thermal performance, long-term stability, and wide range of applicable scenarios. Thermal paste remains suitable for devices with limited budgets and lower heat dissipation requirements. Based on your actual needs, choosing the most appropriate heat dissipation material will help your devices maintain optimal performance.