The Difference between Thermally Conductive Potting Encapsulant and Thermally Grease

- Posted on:2019-12-11 10:50:00

- Source:AOK Thermal Pad Manufacturer Company News

1. What are the characteristics of thermally conductive potting encapsulant?

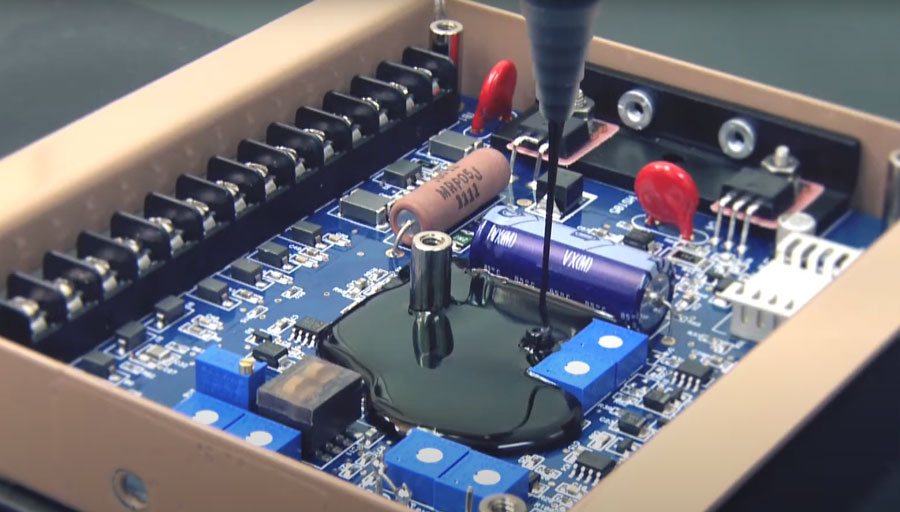

Thermally conductive potting encapsulant is a low-viscosity, flame-retardant, two-component, silicone thermally conductive potting encapsulant, which can be cured at room temperature or by heating. The higher the temperature, the faster the curing. The biggest difference with thermal grease is that thermally conductive potting encapsulant can be cured and has a certain bonding performance.Thermally conductive potting encapsulant is a kind of silicone rubber, which is a single-component room temperature vulcanized liquid rubber.Once exposed to the air, the silane monomers in it will condense to form a network structure, the system is cross-linked, can not melt and dissolve, is elastic, becomes rubbery, and bonds objects. Its thermal conductivity is slightly higher than general rubber, but much lower than thermal conductive silicone grease, and once cured, it is difficult to separate the bonded objects.

2. What are the characteristics of thermal grease?

Thermal grease is a kind of high thermal conductivity insulating organic silicon material. It is not cured and can be used for a long time at a temperature of -50 ℃-+230 ℃ to maintain the state of grease when used. It not only has excellent electrical insulation, but also has excellent thermal conductivity, and at the same time has low oil separation (towards zero), high and low temperature resistance, water resistance, ozone resistance, and weathering resistance. It can be widely applied to the contact surface between the heating element (power tube, thyristor, electric heating pile, etc.) and heat dissipation facilities (heat sink, heat sink, shell, etc.) in various electronic products and electrical equipment. The role of heat transfer media and the performance of moisture-proof, dust-proof, anti-corrosion and shock-proof. It is suitable for surface coating or integral potting of various microwave devices such as microwave communications, microwave transmission equipment, microwave special power supplies, regulated power supplies, etc. This type of silicon material provides excellent thermal conductivity for electronic components that generate heat. Such as: transistors, CPU assembly, thermistors, temperature sensors, automotive electronic parts, automotive refrigerators, power modules, printer heads, etc.

3. The common points and differences between thermal conductive potting encapsulant and thermal conductive silicone grease.

Common point: Both have thermal conductivity and insulation, and are thermal interface materials.The difference: Thermally conductive potting encapsulant: sticky (it is difficult to remove once it is stuck, so most of the time it is used in occasions where only one-time bonding is needed), translucent, high temperature dissolution (viscous liquid), low temperature solidification (exposure), Can not melt and dissolve, flexible. Thermal grease: Adsorbent, non-viscous, paste-like semi-liquid, non-volatile, non-curing (it will not thicken at low temperature, and will not become thin at high temperature).

4. Application

Compared with thermal silica gel, thermal conductive silicone grease is widely used. Many industrial and electronic products require heat dissipation. Moreover, there are many types of thermal conductive silicone grease, and people increase its thermal conductivity by adding some "impurities" to pure thermal conductive silicone grease. These impurities are graphite powder, aluminum powder, copper powder and so on. Pure thermal conductive silicone grease is pure milky white, the color of the silicone grease doped with graphite is dark, the thermal grease doped with aluminum powder is a little gray and shiny, while the silicone grease doped with copper powder is a little yellow.

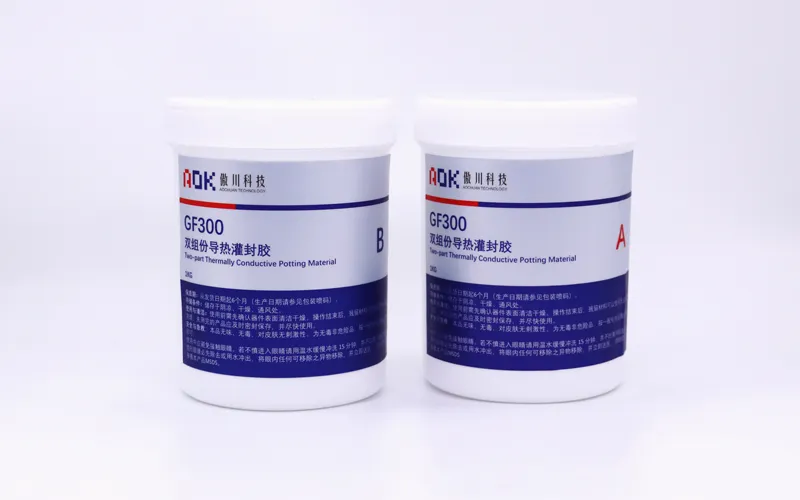

AOK thermally grease is a polymer material synthesized by modern special technology by adding various high thermal conductivity metal oxides and various auxiliary agents as raw materials to silicone resin silicone rubber. Compared with traditional grease with metal For powders, this not only improves thermal conductivity, but also has high insulation, stability and overall performance advantages. For example, AOK's GF100 is a high thermal grease with 3.0w, a high-quality thermal grease with good adsorption and filling effect.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.