Thermal Interface Materials (TIMs) play a crucial role in optimizing heat transfer across devices and components in various electronic systems. They are designed to fill the microscopic air gaps and imperfections between the mating surfaces of heat-generating components (such as CPUs, GPUs, power transistors) and the heat sinks or cooling solutions.

The primary function of TIMs is to enhance thermal conductivity and reduce thermal resistance at the interface, thereby improving heat dissipation. By filling the gaps and minimizing the air voids, TIMs facilitate more efficient transfer of heat from the hot component to the cooling system, ensuring better thermal management and preventing overheating.

Thermal Greases: These are typically silicone-based or metal-based compounds with high thermal conductivity. They are easy to apply and provide good contact between the surfaces, improving heat transfer.

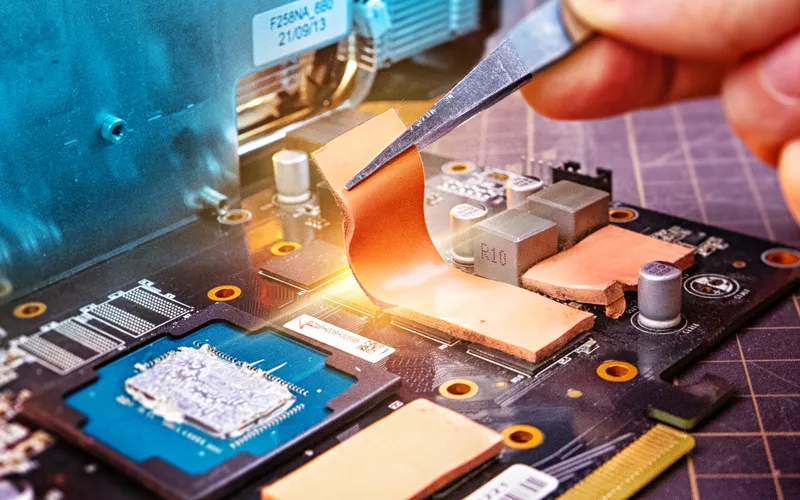

Thermal Pads: These are soft, compressible pads made of materials like silicone, graphite, or phase-change materials. They conform to surface irregularities and provide reliable thermal contact.

Thermal Adhesives: These are used to permanently bond heat sinks or cooling solutions to the components. They provide both thermal conductivity and mechanical attachment.

Phase-Change Materials (PCMs): These materials change their physical state (solid to liquid or vice versa) with temperature variations, allowing for improved thermal contact and heat dissipation.

Gap Fillers: These are highly compressible materials designed to fill large gaps and provide thermal conductivity in applications with uneven surfaces.

Selecting the appropriate TIM depends on factors such as thermal conductivity requirements, operating temperatures, surface finishes, application method, and reworkability, among others. It's essential to choose a TIM that suits the specific needs of the electronic system to ensure efficient heat transfer and optimal thermal performance.

Proper application techniques, such as applying the TIM in the correct thickness and avoiding excessive or insufficient application, are also crucial for maximizing the effectiveness of thermal interface materials. Regular maintenance and replacement of TIMs are generally recommended to ensure consistent thermal performance over time.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com