What Is the Bonding Strength of Thermal Conductive Silicone Grease?

- Posted on:2023-09-18 11:07:00

- Source:AOK Thermal Pad Manufacturer Company News

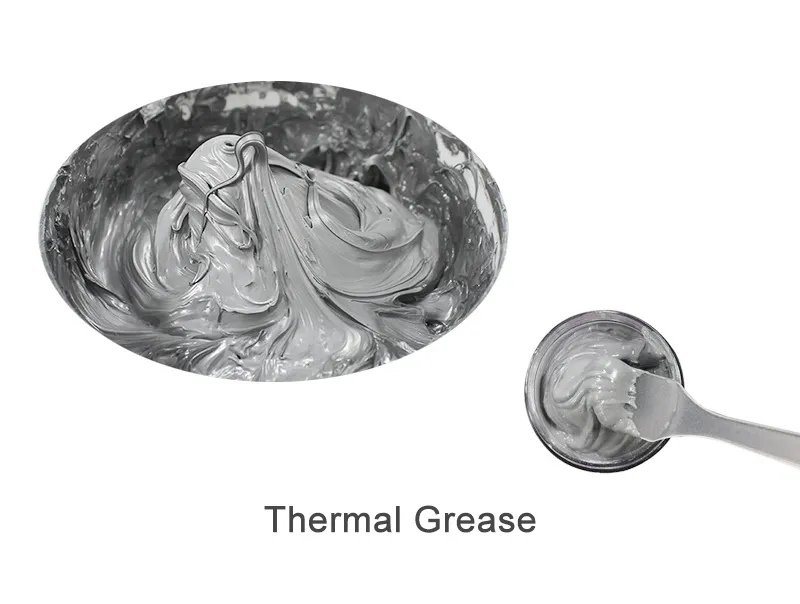

The bonding strength of thermally conductive silicone grease refers to it's bonding force or adhesion in bonding applications. Bond strength depends on factors such as the chemical composition of the thermal grease, surface treatment, contact material, and applied pressure.

Thermal conductive silicone grease mainly improves heat conduction by filling tiny gaps and effectively transfers heat energy to the radiator or other heat dissipation components. Thermal grease typically has lower bond strength than traditional adhesives because it's primary purpose is to provide heat conduction rather than a strong physical bond.

The bonding strength of thermally conductive silicone grease can be affected by the following factors

Surface preparation: Proper cleaning and preparation of contact surfaces is usually required prior to application of thermal grease. A smooth, clean surface helps improve the bonding strength of thermal grease.

Pressure: Proper pressure can help the thermal grease fill gaps and achieve better contact. Applying moderate pressure can improve bond strength, but too much pressure can cause excessive extrusion or deformation.

Temperature: The bond strength of thermal grease generally remains stable over a wide temperature range. However, high temperature environments may cause thermal grease to soften or flow, thereby reducing bond strength.

Material selection: The bonding strength of thermally conductive silicone grease is also affected by the contact material. Different material surfaces may have different adhesion abilities to thermally conductive silicone grease.

Thermal grease is generally not designed to provide a strong physical bond, but to optimize heat conduction. Therefore, when using thermally conductive silicone grease for bonding, you should ensure that you select appropriate bonding methods and materials, and consider other fixing or support structures in the design to provide additional mechanical strength and stability. If higher bond strength is required, other adhesives or structural design improvements may need to be considered to meet the requirements.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com