The 7 Important Data to Look at When Choosing a Thermal Interface Pads

- Posted on:2023-06-07 14:00:00

- Source:AOK Thermal Pad Manufacturer Company News

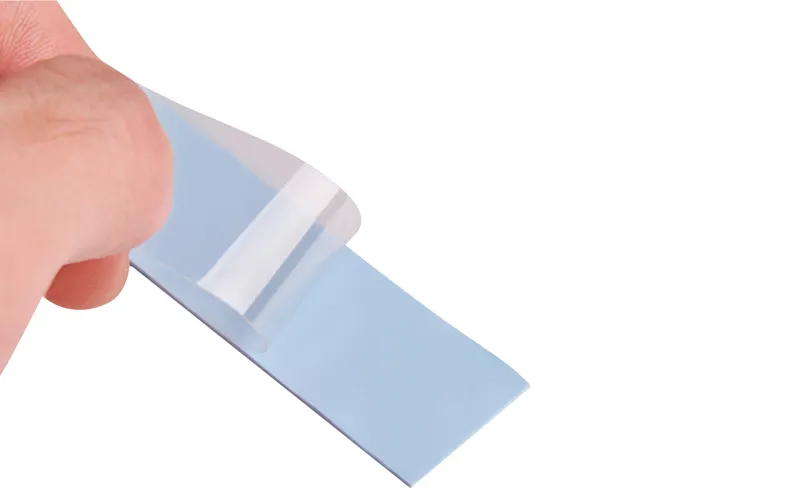

To help you to find and select the best thermal interface pads for your electrical project: We have listed the 7 main technical information to check when selecting a thermal interface pads:

1. Thermal conductivity (independent of thickness), in W/m.K: Thermal conductivity of a thermal interface pads is the fist element that comes in mind when choosing. Thermal conductivity is expressed in W/m.K. It's physically measured by 2 methods: either with a wire or a disk. The contact surface being different, the thermal performances also are. Thermal conductivity measured with a wire will always be better than the one with a disk. The disk measure is the one that best represent reality. it's independent of thickness.

2. Thermal resistivity (dependant on pressure and thickness), in K.in²/W: Thermal resistivity depends on the use of the thermal interface pads. A strong compression and a low thickness reduce thermal resistivity, and thus the efficiency of thermal transfer.

3. Thickness of the gap filler: A thermal interface pads thickness allows to balance the differences in height between a PCB's components. The thinnest thermal interface materials are preferred for the best thermal performances.

4. Hardness (in Shore 00): A thermal interface pads hardness determines it's ability to deform and the compression forces required. Using on components a thermal interface pads that is too hard may damage the whole.

5. Volume resistivity of the gap filler, in Ohm.m: It corresponds to the electrical resistance of the thermal interface pads. That is to say, it's ability to avoid creating short circuit's when it comes in contact with the conductive parts of the components.

6. Breakdown Voltage in KV/mm: The breakdown voltage is the voltage above which there is a high risk of electrical arc (thus of short circuit). This voltage depends on the thickness. The thinner the thermal interface pads, the greater the risk. The breakdown voltage is particularly high on polymer-based thermal interface pads. Be careful however to compress the thermal interface pads evenly to avoid creating an electrical arc somewhere the thermal pads has been compressed more.

7. Usage temperature range and fire resistance: Most of thermal interface pads manufacturers guarantee use from -40 ~ 150°C. In real life, as thermal interface pads are silicone-based (melting point > ~ 1400°C), they can resist more than 200°C.

You will understand after this article that the choice of thermal interface pads depends on many parameters. Fortunately, that also means that lots of possibilities and alternatives exist on the market. Please contact us to guide you in the choice of your thermal interface pads in order to reach the best ratio in terms of performance/cost/quality.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com.