How Should I Store Thermal Gap Filler Materials?

- Posted on:2023-07-12 09:32:00

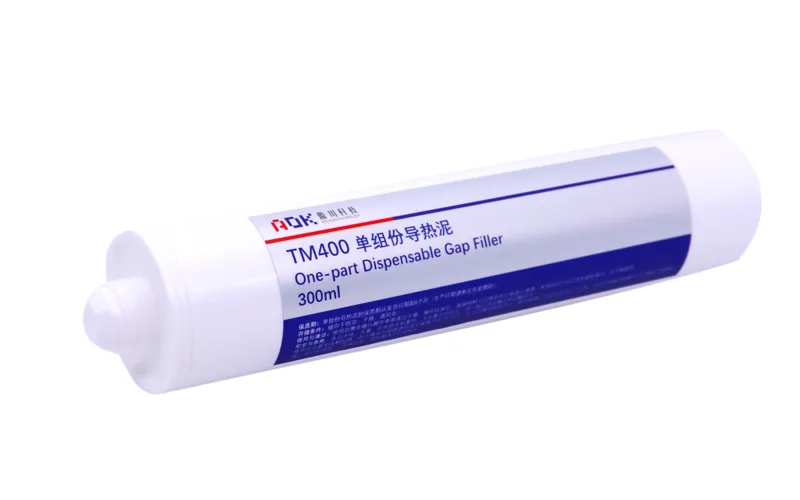

- Source:AOK Thermal Pad Manufacturer Company News

Thermal gap filler materials are typically made of soft, compressible materials such as silicone, rubber, or foam that are used to fill gaps between two surfaces to improve heat transfer and thermal management. To store thermal gap filler materials properly, here are some general guidelines:

Keep the material in it's original packaging

The original packaging of the thermal gap filler material is designed to keep it clean, dry, and protected from contaminants. Therefore, it's best to keep the material in it's original packaging until you are ready to use it.

Store in a cool, dry place

Thermal gap fillers can be sensitive to temperature and humidity, so it's important to store them in a cool, dry place away from direct sunlight, moisture, and extreme temperatures. Ideally, the storage temperature should be between 15 ~ 25°C (59 ~ 77°F), and the relative humidity should be below 50%.

Avoid stacking or crushing

Thermal gap filler materials are often soft and compressible, so it's important to avoid stacking or crushing them during storage, as this can cause damage and reduce their effectiveness.

Rotate stock

If you have a large quantity of thermal gap filler material, it's a good idea to rotate your stock regularly to ensure that the oldest material is used first. This can help prevent the material from becoming unusable due to aging or degradation.

Avoid exposure to chemicals

Thermal gap fillers can be sensitive to certain chemicals, so it's important to store them away from any sources of chemical contamination. This includes avoiding storage near solvents, oils, acids, or other chemical substances that could react with or degrade the material.

Check expiration dates

Like any other material, thermal gap fillers have a limited shelf life, and their effectiveness can degrade over time. Be sure to check the expiration date on the packaging and use the material before it expires. If you are unsure about the shelf life of your specific thermal gap filler material, consult the manufacturer's instructions or contact their technical support for guidance.

Keep away from moisture

Moisture can cause thermal gap fillers to degrade or lose their effectiveness, so it's important to keep them dry. If the material is not in it's original packaging, store it in an airtight container or bag to prevent moisture from getting in.

Handle with care

Thermal gap fillers are often delicate, and rough handling can damage or deform them. When handling the material, be gentle and avoid excessive pressure or bending.

Store in a controlled environment

If you have a large quantity of thermal gap filler material, consider storing it in a controlled environment, such as a warehouse or storage room with controlled temperature and humidity levels. This can help ensure that the material remains effective for longer periods.

By following these additional guidelines, you can help ensure that your thermal gap filler material remains effective and usable for as long as possible, improving the thermal management of your devices and equipment.

If you would like to learn more about AOK performance thermal materials, please visit our website at www.aok-technologies.com